Perfect solutions for gentle and fast mounting of rolling bearings

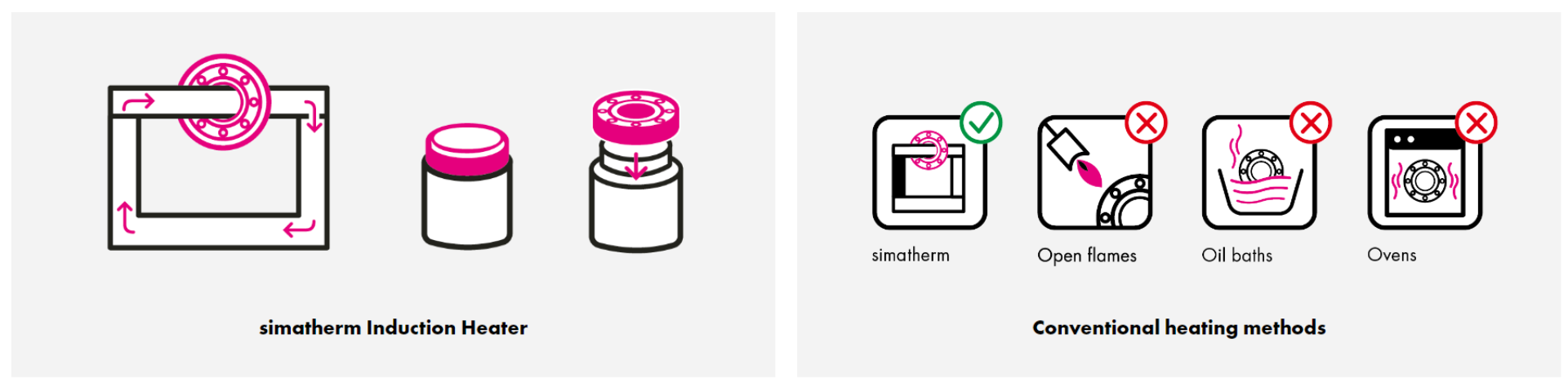

simatherm heating devices can be used to efficiently heat rolling bearings and other ring-shaped metal parts. They enable fast and clean assembly and replace conventional heating methods such as hotplates, hot oil baths, open flames and ovens. During the heating process, only the workpiece heats up, but the device remains cold. simatherm induction heating devices are used for workpieces weighing up to 300 kg.

| Precise, even, quick heating | User friendly |

| Automatic demagnetisation | Increased operational safety |

| There is no risk of damage (from excessive mechanical stress, open flames, dirty oil baths, excessively hot ovens and plates) | Selectable power reduction for heating up smaller parts |

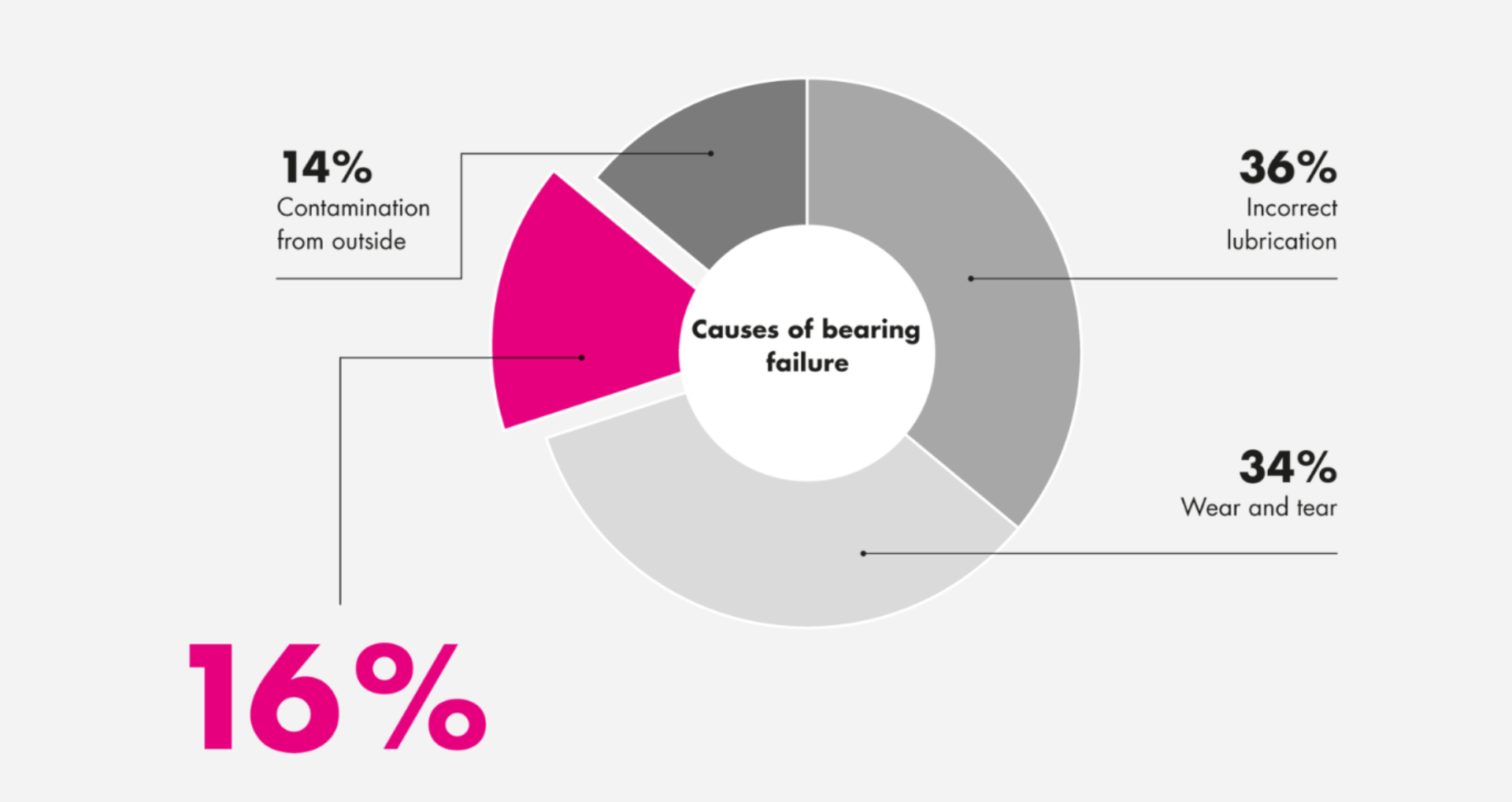

Prevent premature bearing failure

Over 16% of premature bearing failures are caused by improper installation. The lack of proper tooling and know-how often leads to new bearings being subjected to high levels of stress and subsurface damage. This makes premature bearing failure inevitable. In order to prevent this, the correct procedure should be employed using professional, specialist tools throughout the installation process. Only in this way will the new bearings reach their expected service life.

Heating with induction

The heating of rolling bearings and ring-shaped metal parts by induction has proved to be an excellent method for installing these parts with both speed and care. An alternating electro-magnetic field induces a high current directly in the workpiece and raises this precisely to the prescribed installation temperature in a controlled manner.

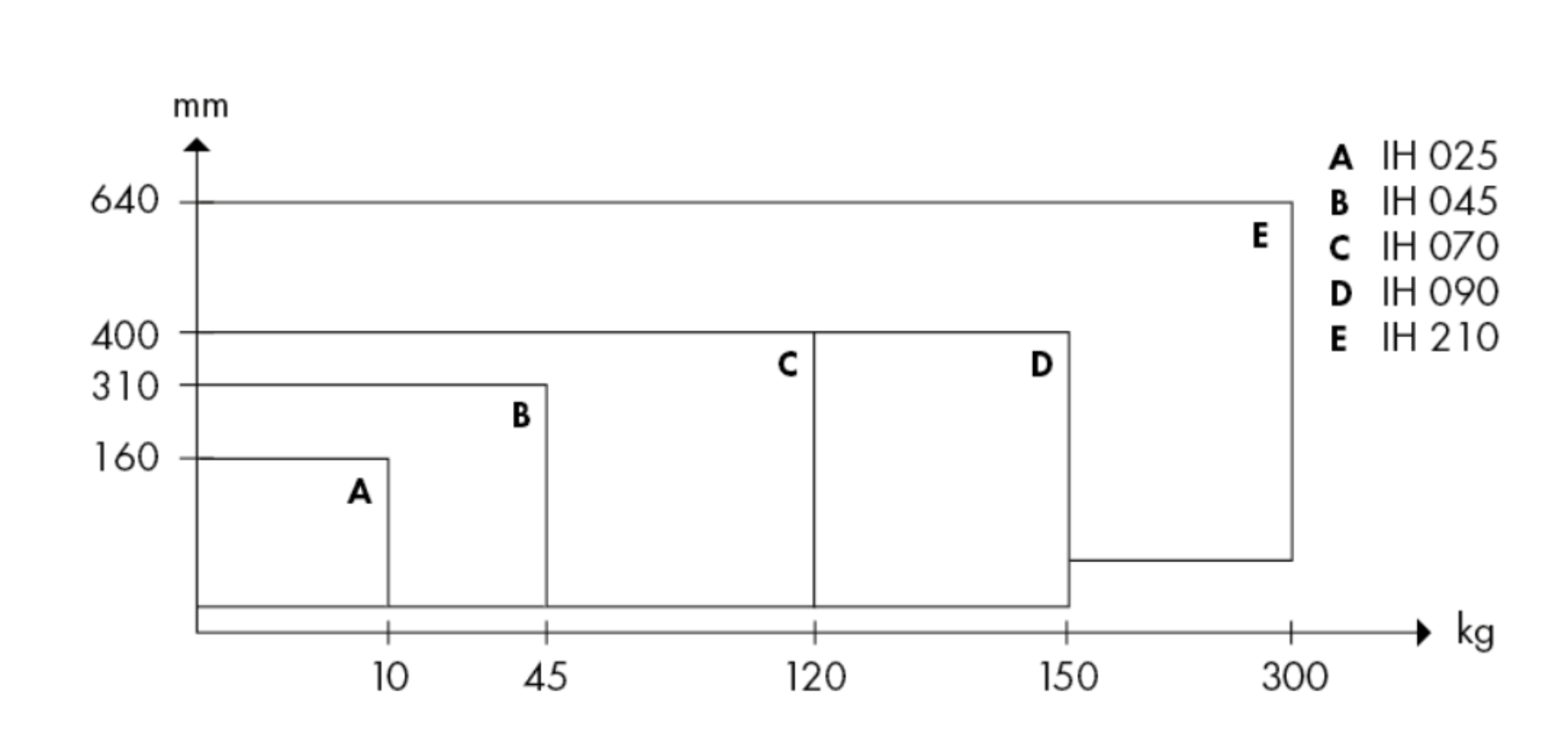

Selection table for simatherm induction heaters

The selection of the appropriate simatherm heating device depends essentially on the dimensions and weight of the workpieces:

Application areas

| Where induction heaters are used | Typical applications |

|---|---|

| Vehicle industry | Bearings |

| Gear box manufacture | Gearwheels |

| Manufacture of electric motors | Sprockets |

| Manufacturer of pumps | Compression rings |

| General engineering | Labyrinth rings |

| Maintenance and repair workshops | Sleeves |

| Joints |

Various simatherm models

Éprouvé des millions de fois et parfaitement adapté à la lubrification de points individuels à l'aide d'huile ou de graisse.

Le graisseur automatique simalube assure l'alimentation en lubrifiant de tous le points de graissage, 24 heures sur 24, jours après jour.

Un roulement insuffisamment ou incorrectement lubrifié présentera des défaillances bien avant d'avoir atteint sa durée de vie théorique. Les distributeurs de lubrifiant ou graisseurs simalube assurent d'une alimentation régulière en graisse en respectant le dosage prescrit. Les durées d'immobilisation sont réduites et les coûts sont nettement revus à la baisse par rapport au graissage manuel fastidieux.

Le graisseur simalube s'installe en quelque secondes au point de lubrification. Lors de la mise en service, une cellule de dégagement de gaz permettant l'injection du lubrifiant dans le point de graissage est activée. La quantité de graisse est réglable en continu à l'aide d'une clé Allen.

Rempli d'huile, simalube est utilisé pour le graissage automatique par exemple de chaînes, de transmissions ouvertes ou de rails de guidage.