Quality tools for the installation and removal of bearings and seals

Without the right special tools, the professional mounting and dismounting of bearings and shaft seals is simply impossible. With simatool tools, rolling bearings and radial shaft seals can be fitted and removed quickly and safely. The well thought-out tools are ergonomically optimally designed and have also been tried and tested in practice. As a result, all work can be carried out significantly faster, safer and more gently without damaging neighboring machine elements.

- Reduction of costs through proper installation and removal

- Longer service life of the components

- No damage to adjacent components when defective parts are removed

- High-quality, specially developed tool sets

- Increased occupational safety

- User-friendly - brief instructions for use directly in the case

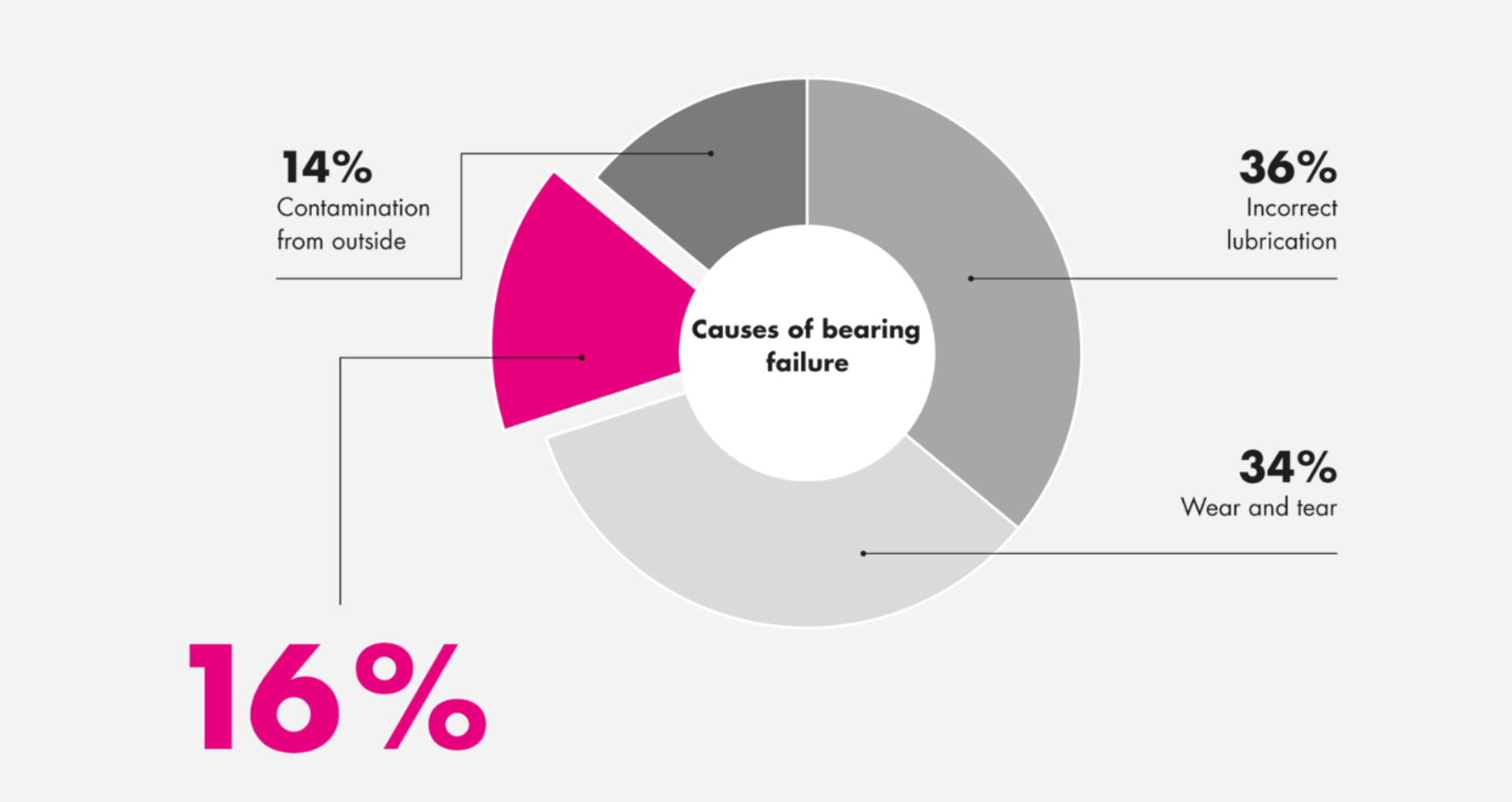

Prevent premature bearing failure

Over 16% of premature bearing failures are caused by improper installation. The lack of proper tooling and know-how often leads to new bearings being subjected to high levels of stress and subsurface damage. This makes premature bearing failure inevitable. In order to prevent this, the correct procedure should be employed using professional, specialist tools throughout the installation process. Only in this way will the new bearings reach their expected service life.

Areas of application

- Vehicle industry

- Gear box manufacture

- Manufacture of electric motors

- Manufacturer of pumps etc.

- General engineering

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.

Discover our fully automatic lubrication solutions at Pomac Lub-Services or browse the ILC range