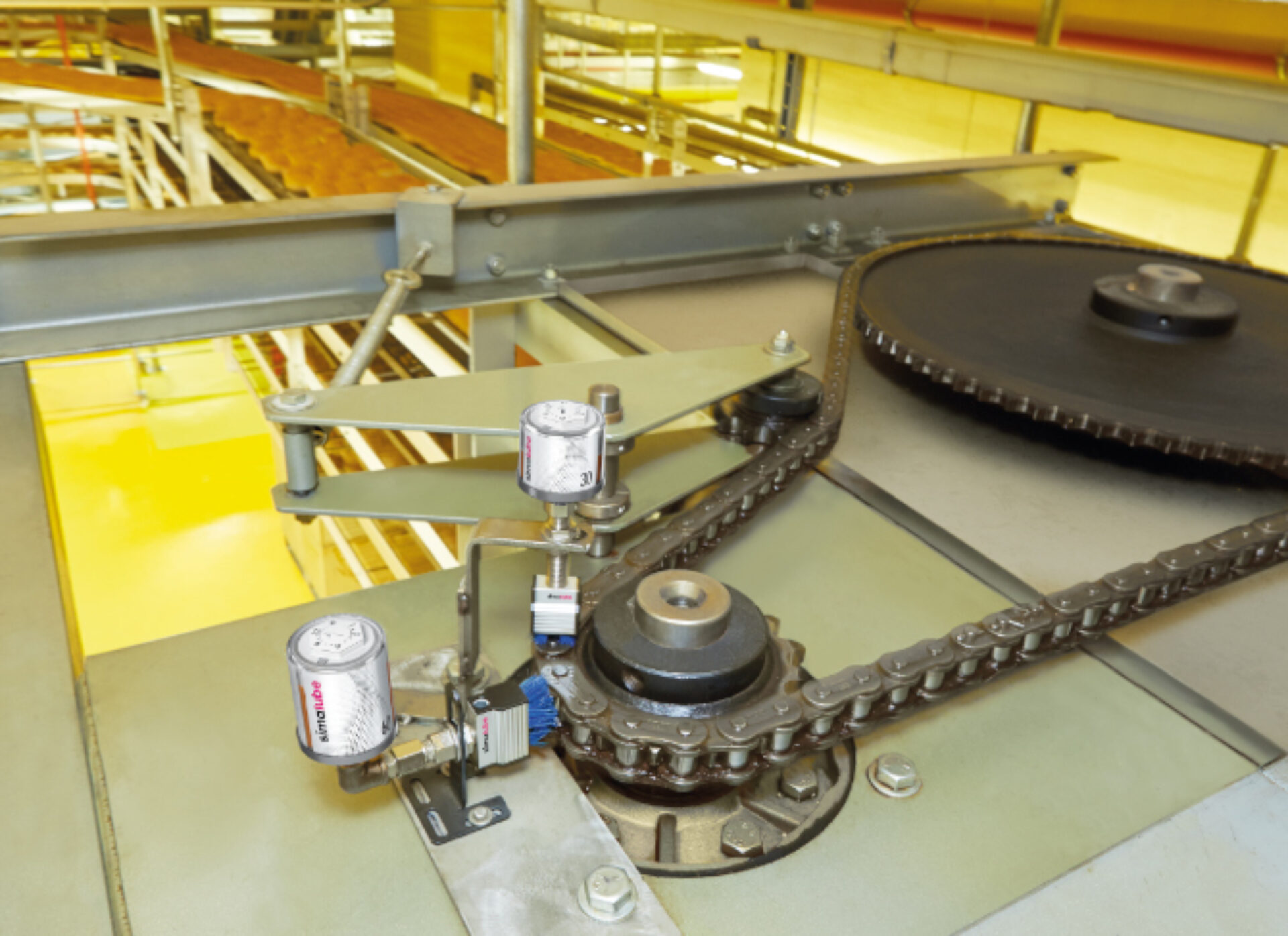

Conveyor technology as a subdiscipline of mechanical engineering comprises all equipment for transporting unit loads or bulk materials. However, continuous conveyors are subject to high loads in terms of utilization, location and operating times. And this is where the simalube lubricator comes in, because this environment is made for it. Continuous lubrication by the simalube relieves the strain on all conveyor components and brings many advantages: fewer operating failures, reduced risk of corrosion, fewer malfunctions, longer machine running times and many other benefits.

| CHALLENGES | SOLUTION |

|---|---|

| Environment: high temperatures, high temperature fluctuations, strong sunlight, heavy pollution | Ideally, the dispensers are mounted directly on the lubrication points. In case of strong vibrations, the simalube must be mounted remotely. For long hose lines, the IMPULSE connect, with which a higher pressure can be achieved, is used. |

| Technical: high loads, strong vibrations, high operating temperatures | |

| Installation: poor accessibility, little space, partially increased back pressure, risk of damage from bulk goods |

Advantages

Advantages of the simalube lubrication system

- Fresh lubricant is continuously fed in

- Due to the continuous supply of lubricant in small quantities, less lubricant is required overall

- Hard-to-reach lubrication points are reliably supplied with lubricant

- Personnel are less often exposed to hazards such as great heights, climbing ladders, etc.

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.