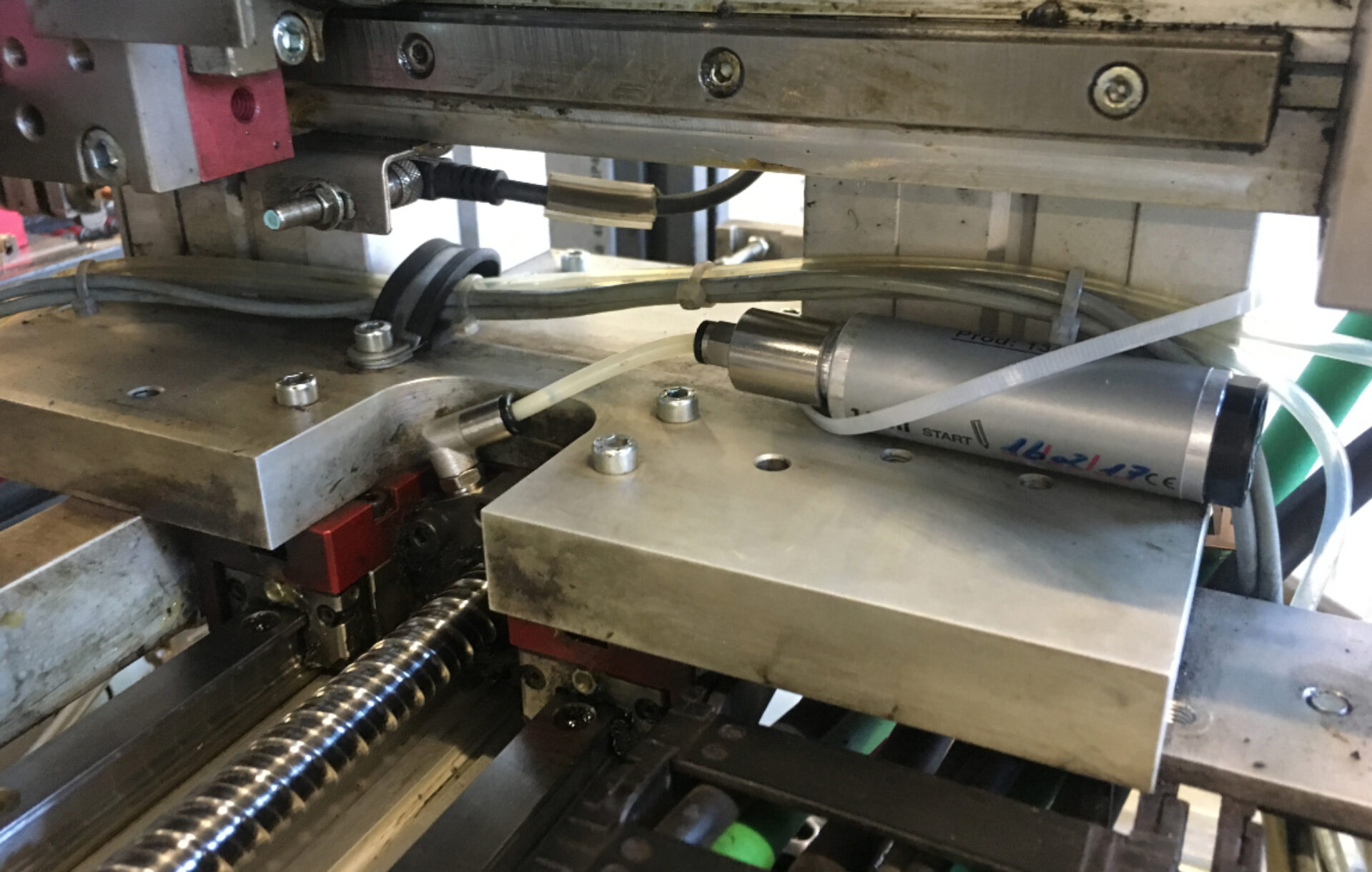

Threaded spindles, sometimes also called drive screws, are machine elements which, together with other elements in a screw drive, serve to convert a rotary movement into a translatory movement.

| CHALLENGES | SOLUTION |

|---|---|

| Environment: pollution, high loads, large forces, high circulation speeds and accelerations | The lubricant is applied via a brush or directly to the components |

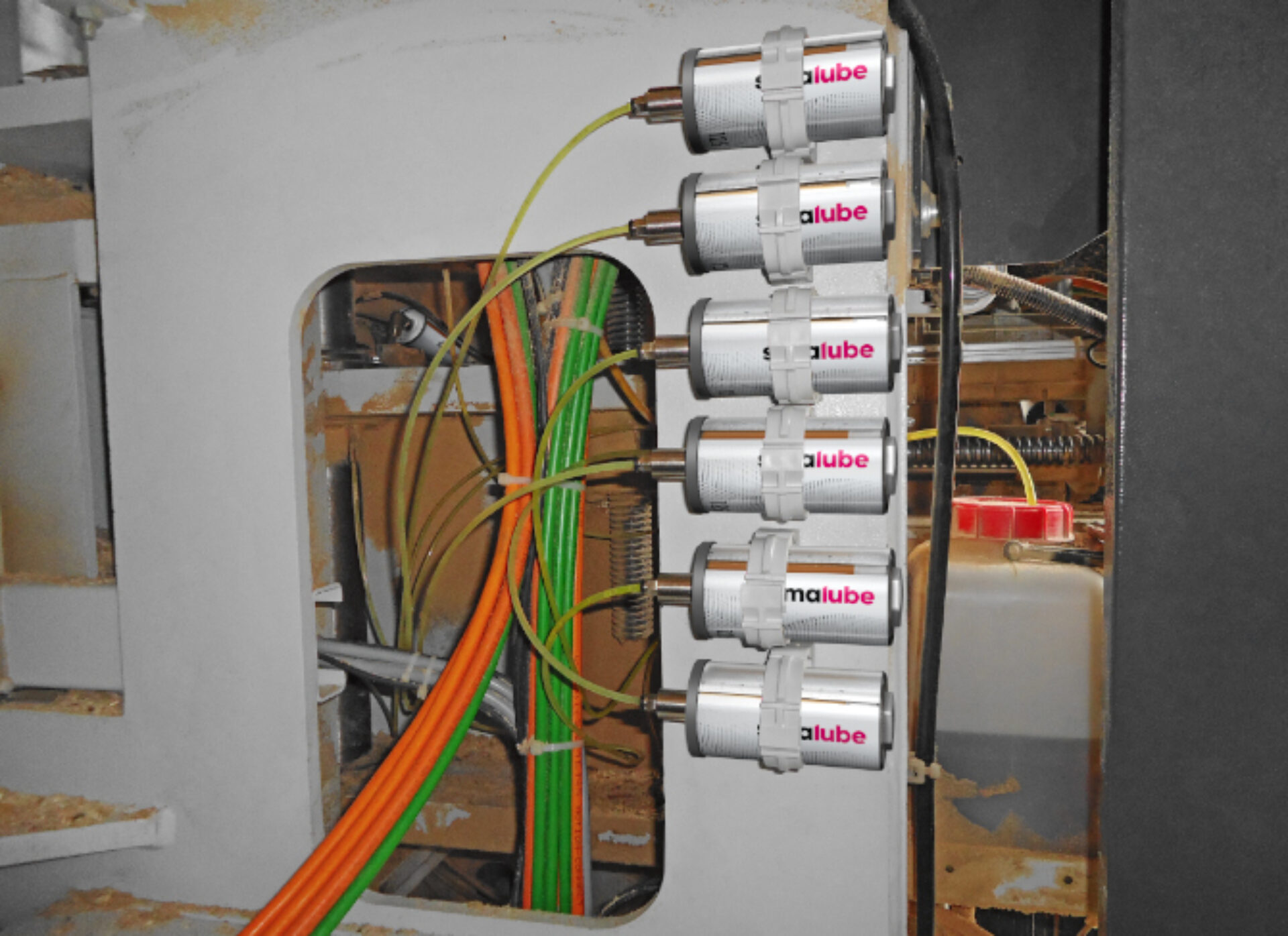

| Installation: little space, very small connection threads | Direct or indirect assembly. The dispenser is connected directly or via a hose to a brush or directly to the nut of the spindle |

Advantages

Advantages of the simalube lubrication system

- Fresh lubricant is continuously supplied

- If the lubricant is continuously supplied in small quantities, much less lubricant is required

- Hard-to-reach lubrication points are reliably supplied with lubricant

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.