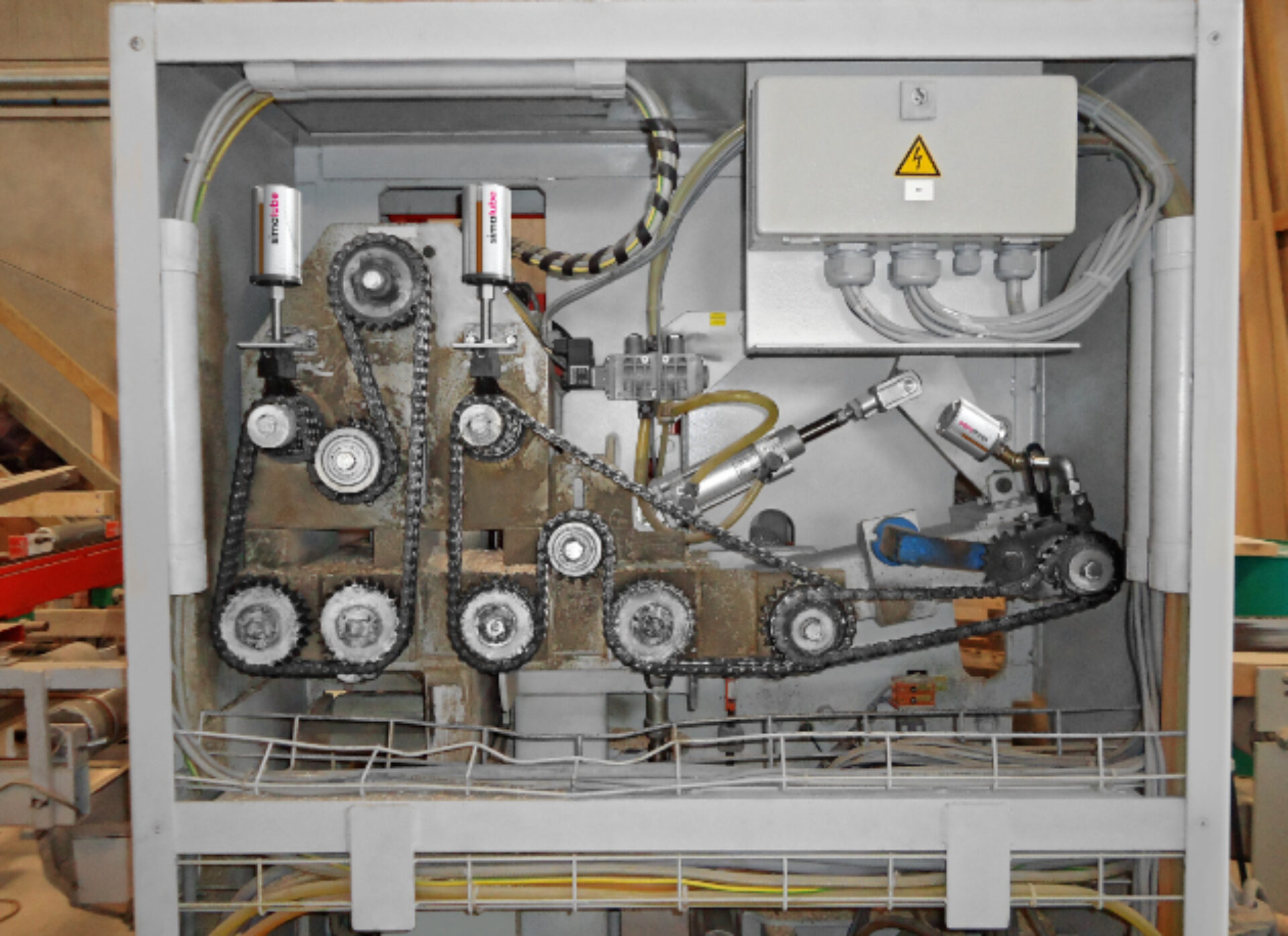

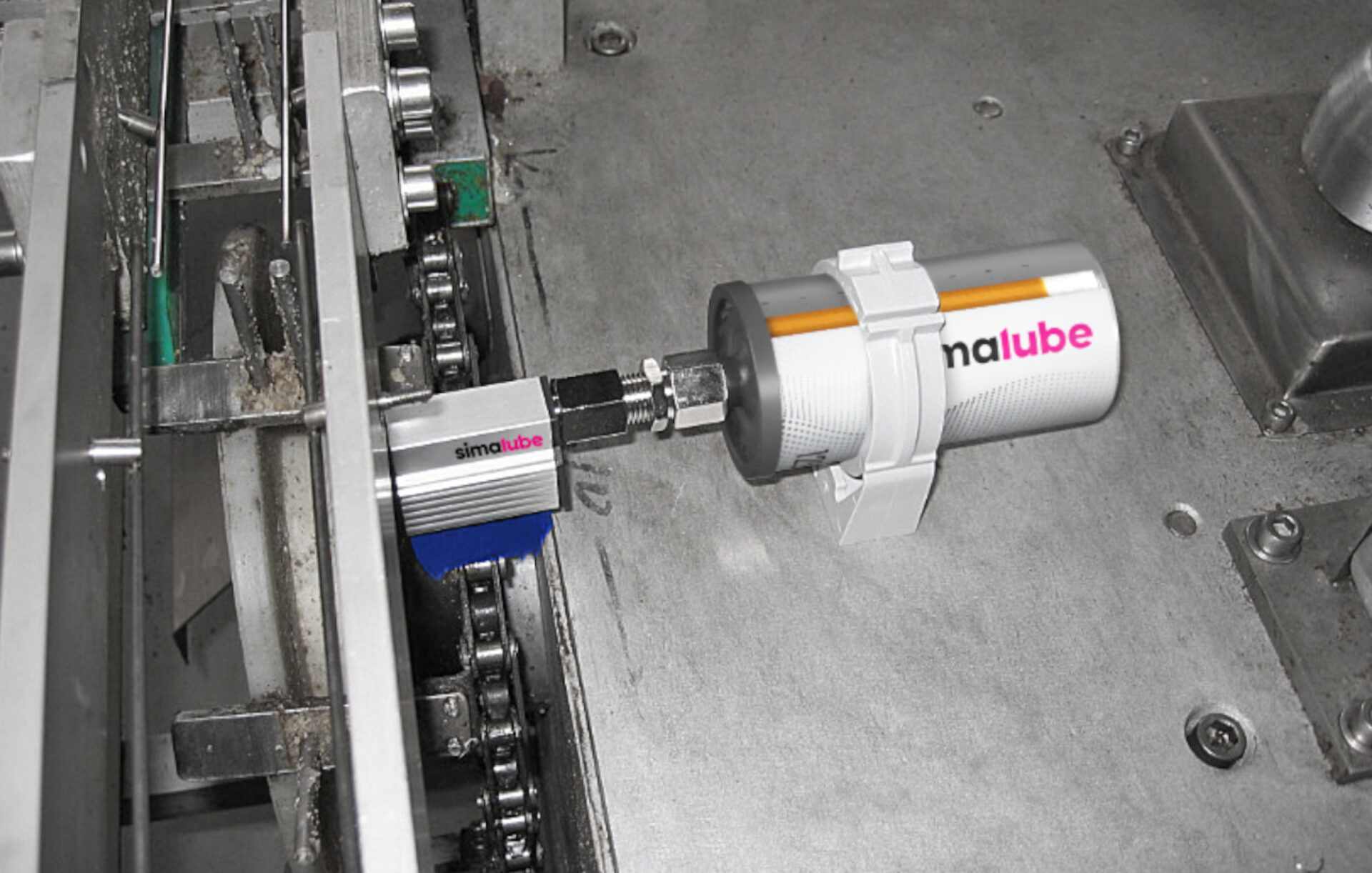

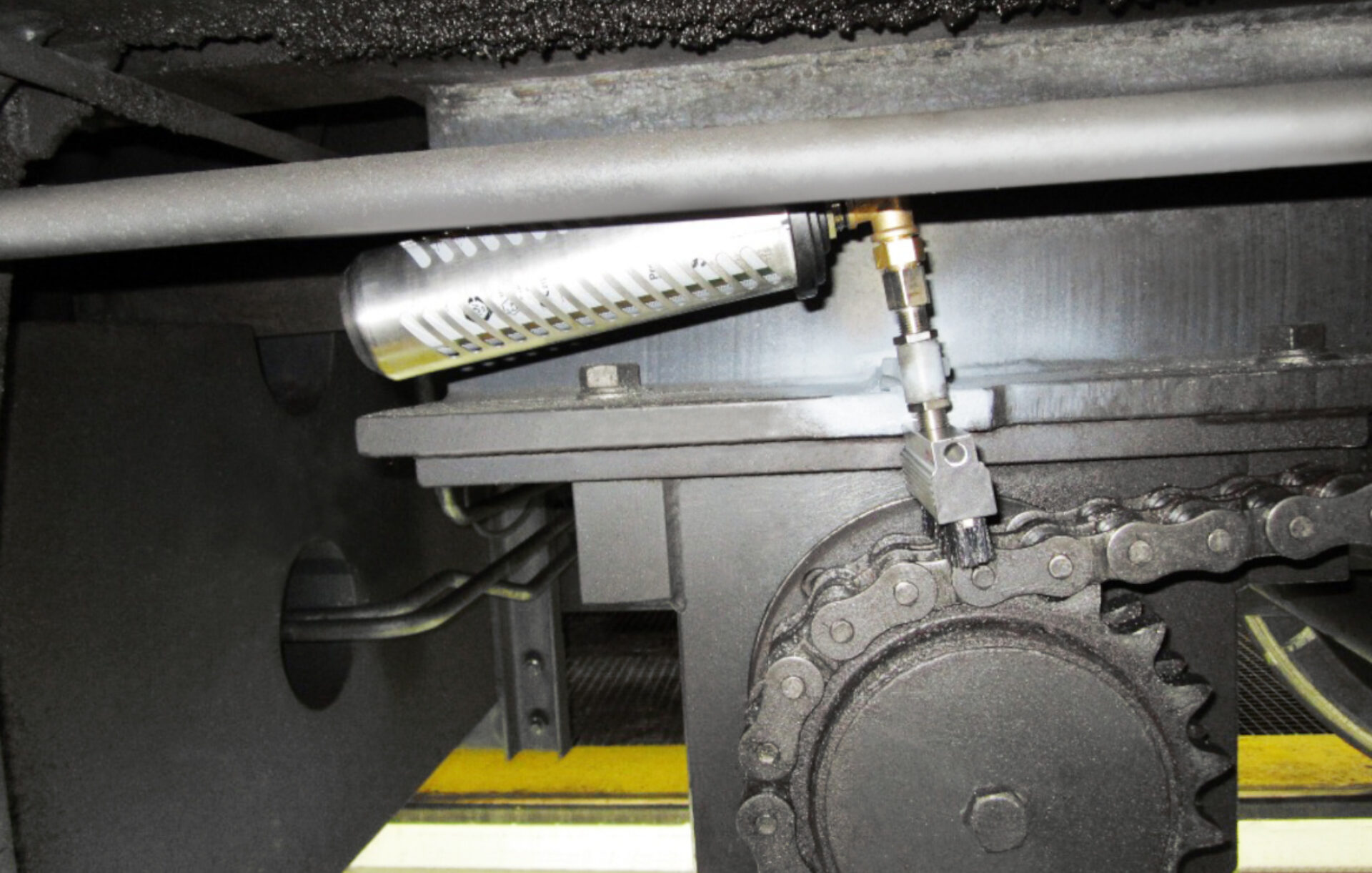

Simalube lubricates chains in any industrial environment, efficiently and reliably. Continuous lubrication with simalube prevents premature damage, reduces maintenance costs and increases functional reliability. In operating environments where there is a lot of dirt and dust, cleaning the chains is as important as their lubrication. By using simalube brushes, this cleaning is permanently ensured. Thanks to the comprehensive simalube accessory range, the lubricant dispenser can be optimally and professionally installed and adjusted for the corresponding chain applications in conjunction with different-sized brushes. The exact dosage and precise delivery signicantly reduce lubricant consumption.

| CHALLENGES | SOLUTION |

|---|---|

| Environment: pollution, high humidity - corrosion, high temperatures | The lubricant is applied to the chains via a brush |

| Technical: high loads | The dispenser can be mounted directly on the brush, the dispenser and brushes can also be connected by means of a hose line |

| Installation: little space, risk of collision, most different sizes and designs |

Areas of application and advantages

| simalube applications for typical chain uses | Advantages of the simalube lubrication system |

|---|---|

| Conveyor belts and chains | No oil drops on the floor, no contamination of the surrounding area |

| Escalators | Reduced servicing and maintenance costs: manual lubrication eliminated, meaning less inconvenience and massive time savings |

| High-speed chains | Rust, noisy operation and squeaky chains avoided through the use of simalube chain lubricant |

| Slat-band and roller chains | No need to turn off the machines for servicing |

| Hinges, slipways and slide rails | Chain service life considerably extended thanks to precise lubrication |

| Drying systems | Convenient solution for each type of chain due to individually deployable accessories |

| Chain drives | Once installed, the chains are reliably and continuously lubricated and cleaned |

| Transport facilities | |

| Washing facilities |

| simalube lubricants | simalube accessories |

|---|---|

| SL14 (chain oil, EP) | Flat brushes |

| SL15 (high-temp. chain oil, EP) | Flat brushes with lateral connection |

| SL18 (food oil, NSF H1) | Round brushes |

| SL19 (biodegradable chain oil) |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.