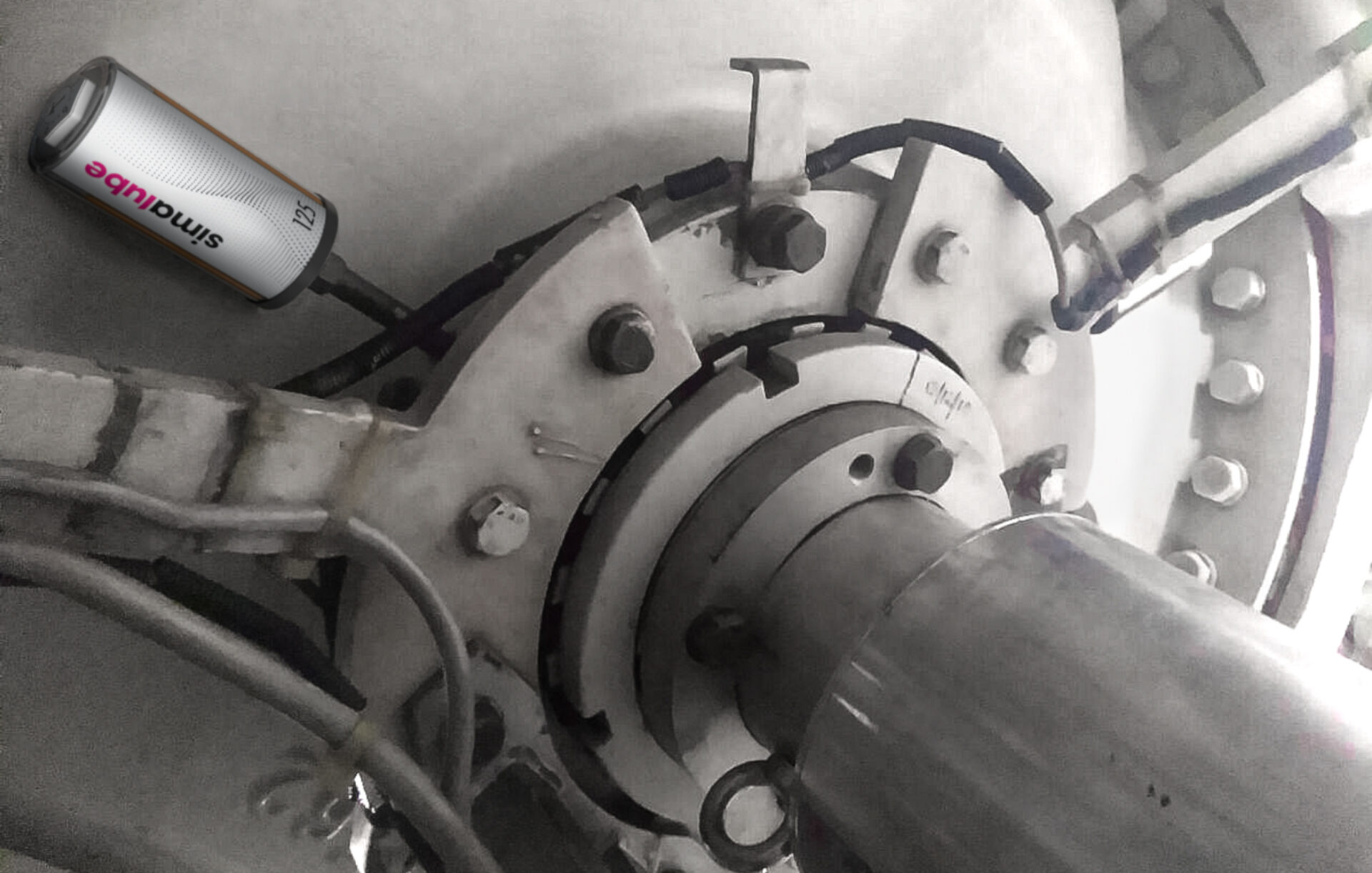

Every wind turbine has a multitude of lubrication points which have to be supplied at regular intervals. Since wind turbines are often located in remote locations, maintenance and the related lubrication is associated with a great deal of time and expense. Extreme temperature fluctuations, humidity and moisture are heavy burdens on every wind turbine. In order to prevent the resulting damage, optimum lubrication is indispensable. With the simalube lubrication system, wind farm operators can minimize the risk of downtime and also increase the efficiency of their wind turbines.

| Challenges | Solution |

|---|---|

| High demands on the availability of the systems | Simalube 60, 125 and 250 ml |

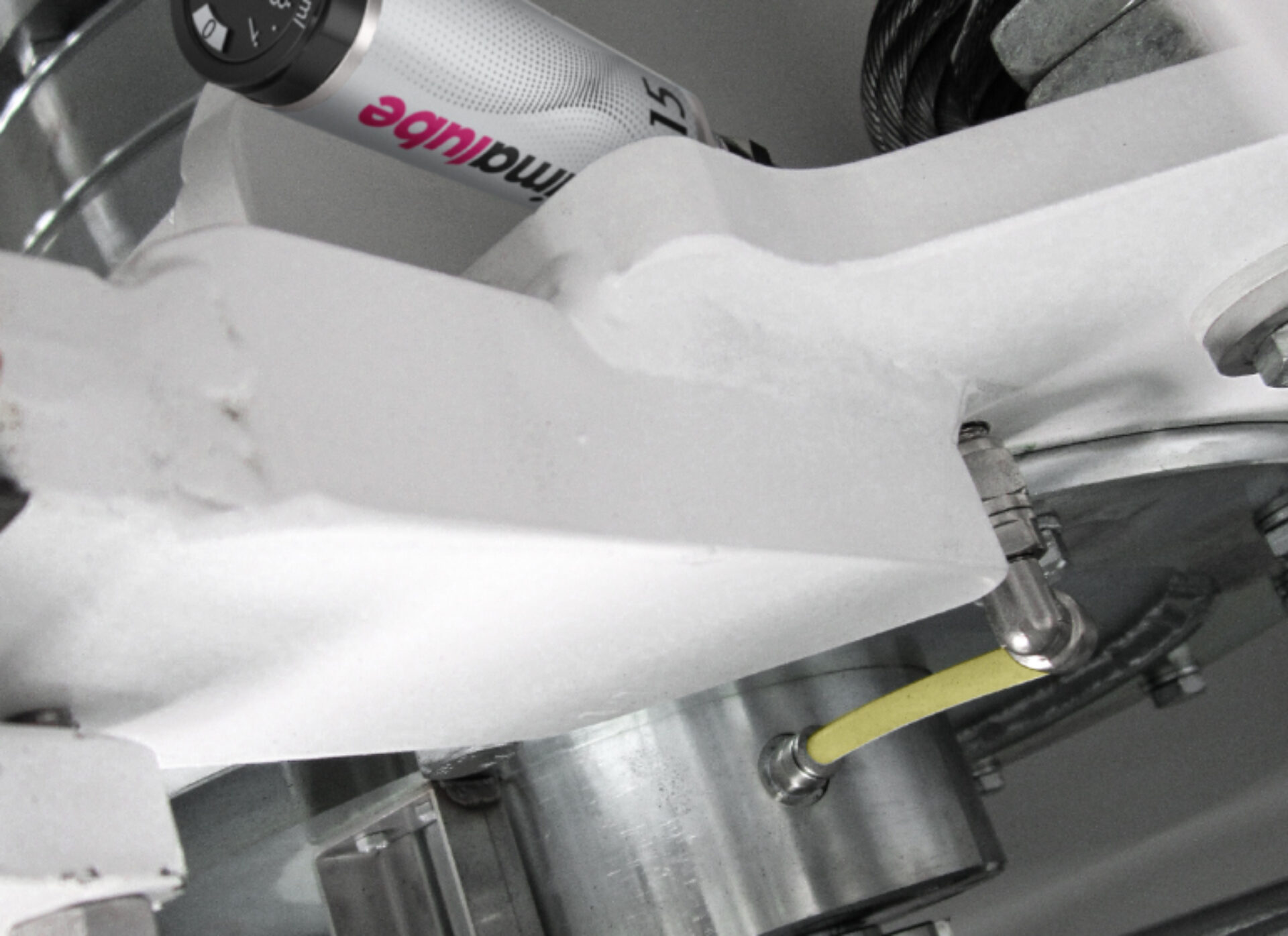

| Large seasonal temperature fluctuations | Installation direct, the lubricant is often supplied to the lubrication point via a lubrication pinion |

Areas of application and advantages

| Simalube areas of application for wind turbines | The benefits from automatic lubrication | Advantages of the Simalube lubrication system |

|---|---|---|

| Rotor blade adjustment | Increased operational safety | Reduction of service requirements and maintenance costs (manual lubrication is no longer necessary, thus there is less required labour and the time savings are great) |

| Rotor blade bearings | Reduced downtime | It is not necessary to shut down the machines during maintenance |

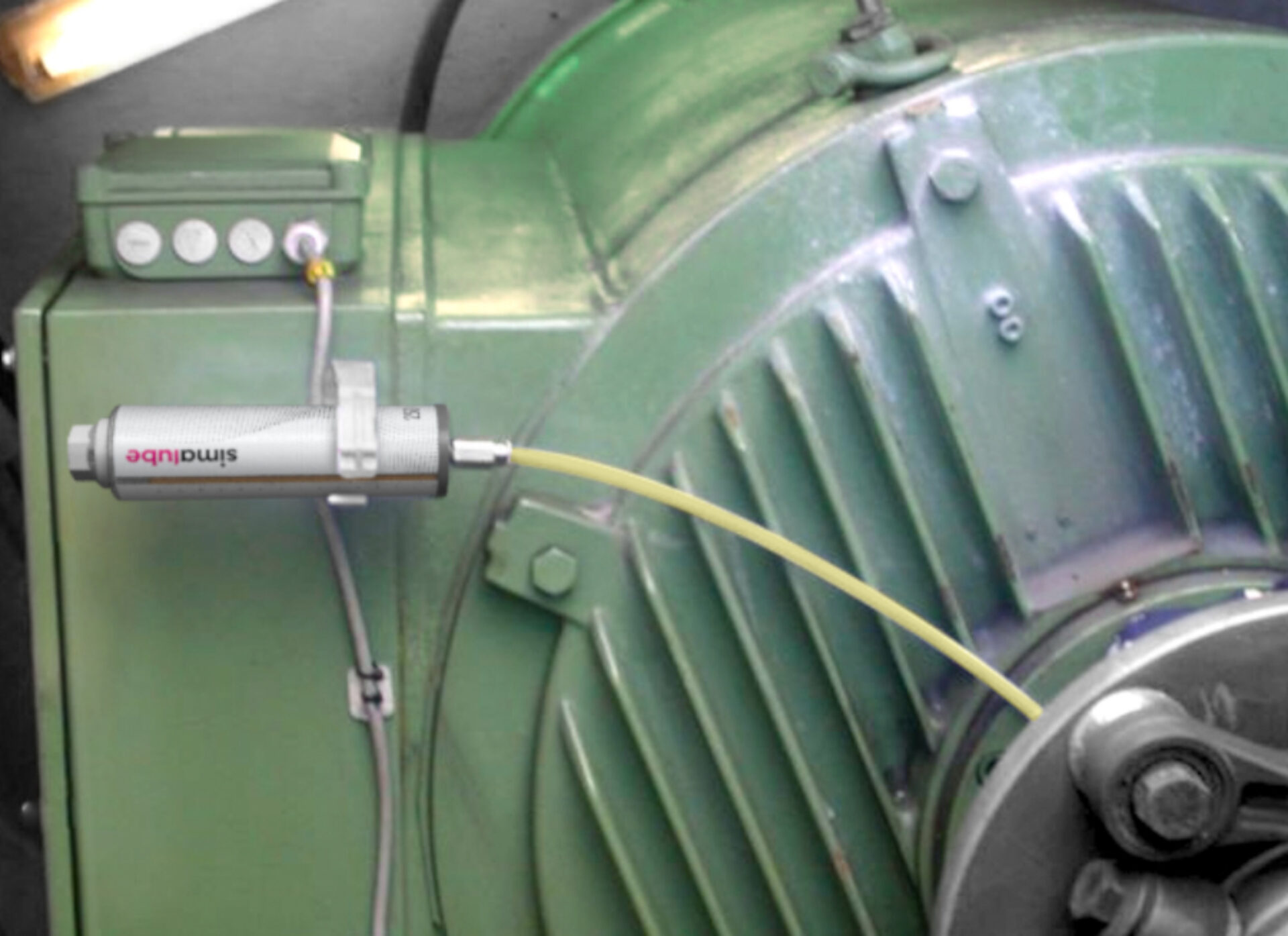

| Generator | Constant supply of hard to reach lubrication points | Longer service life of machines thanks to continuous and precise lubrication |

| Yaw drive | Less time spent on maintenance | Flexibility: The running time is adjustable from 1–12 months |

| Gearboxes | Reduction of wear and longer life of the components | Only one type of lubricator is needed per application. This allows a reduction of storage costs |

| Pitch adjustment (variable speed gear unit) | ||

| Main bearings |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.