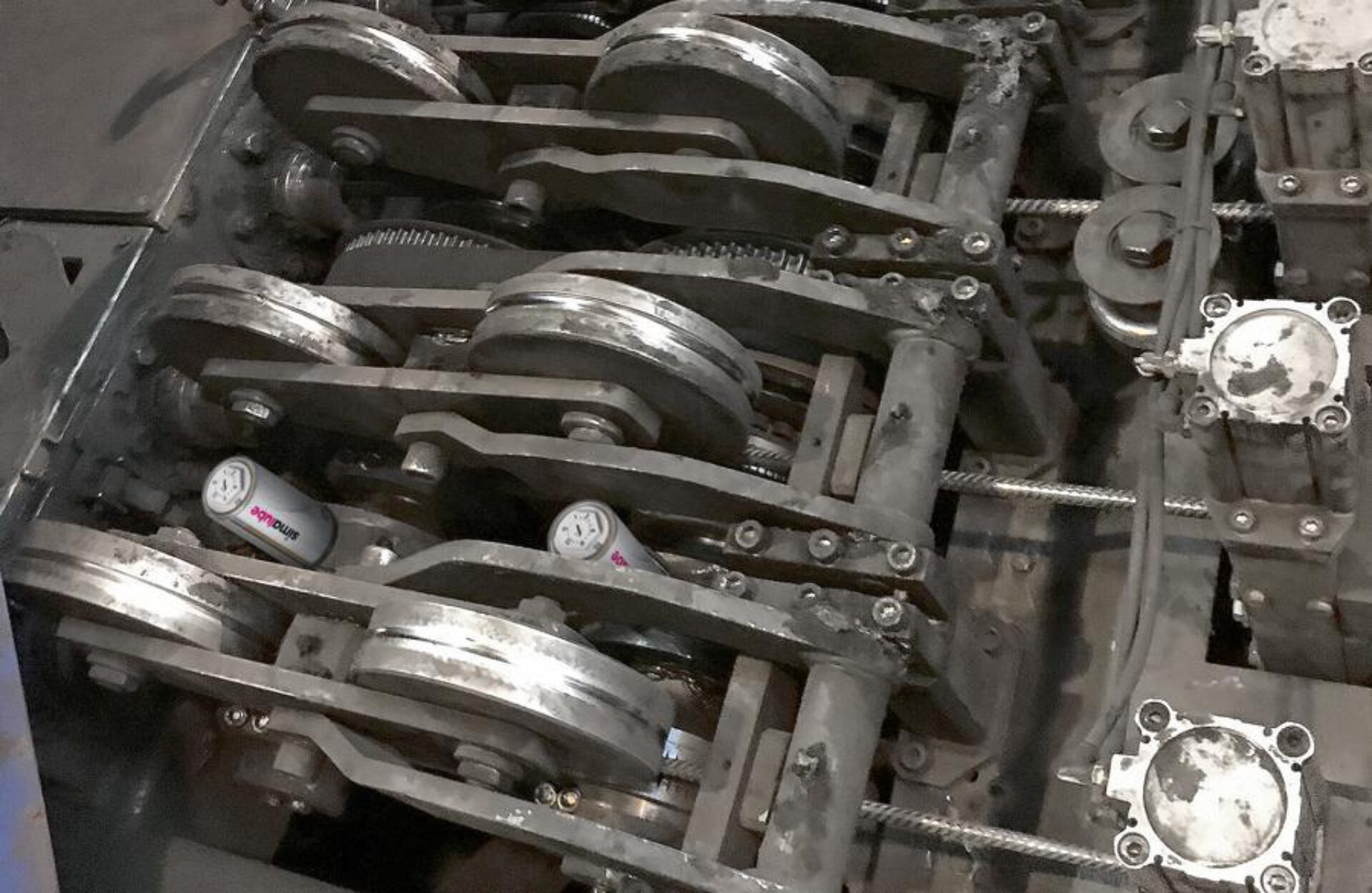

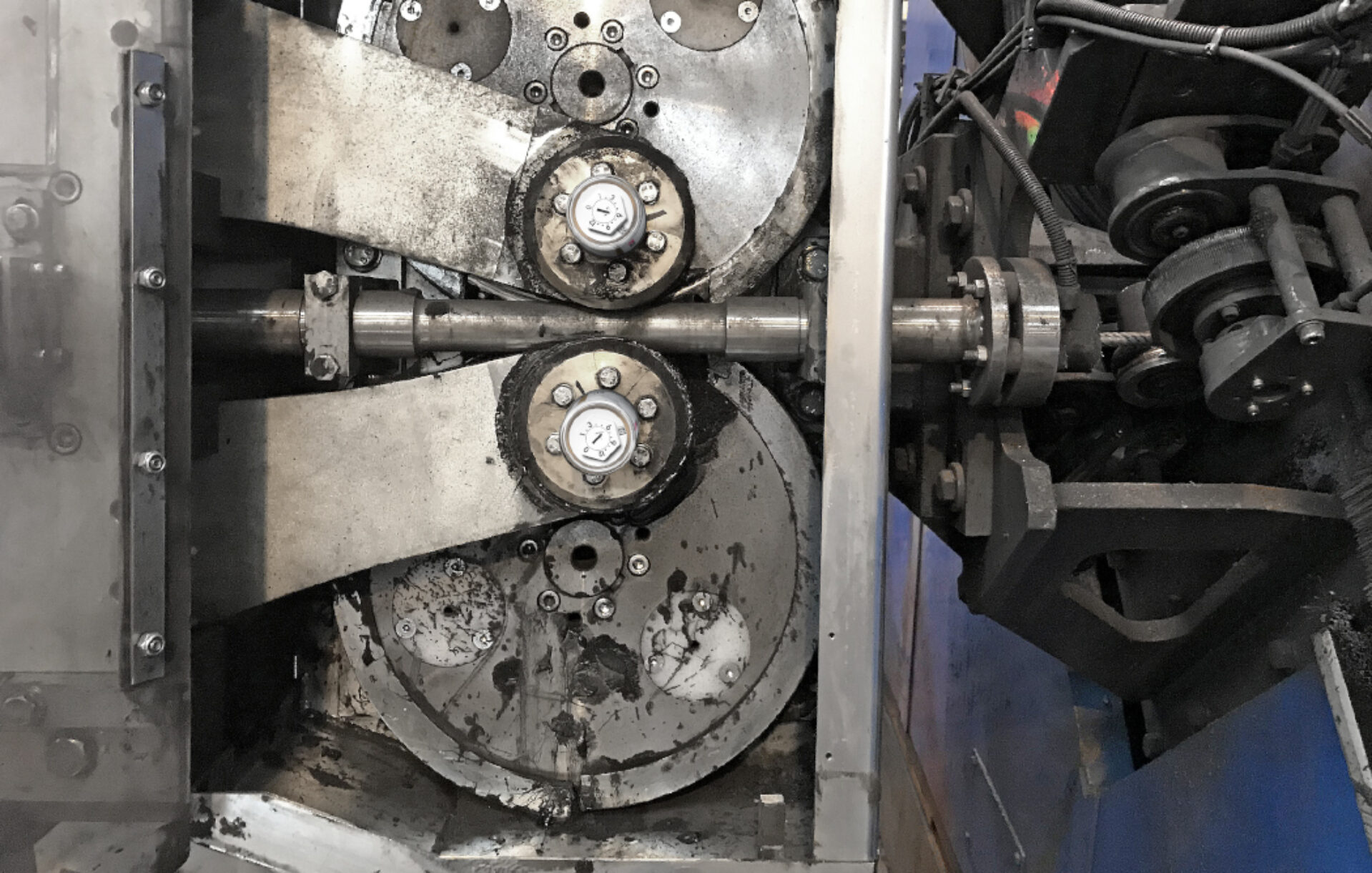

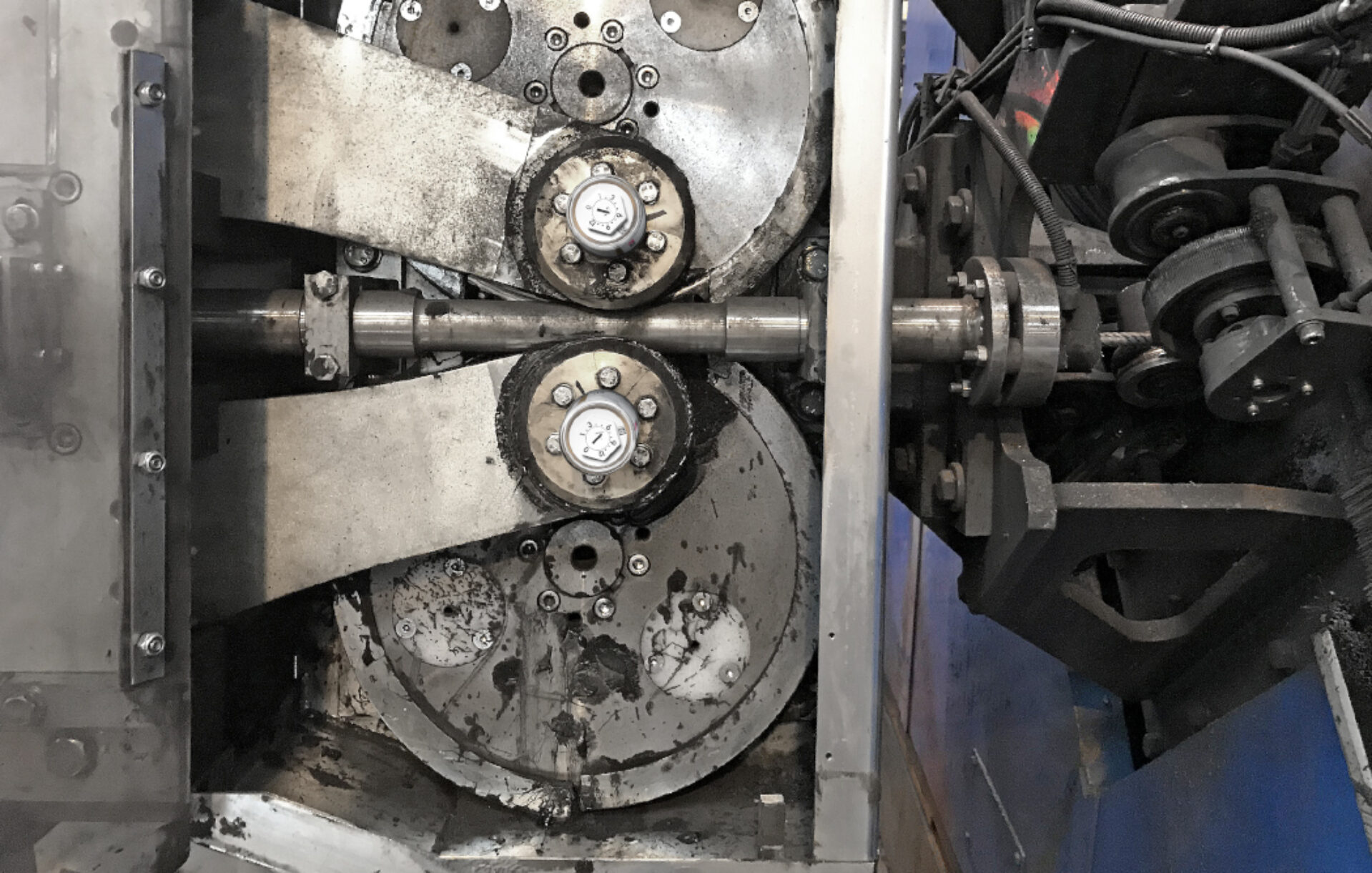

The severe working conditions in the steel industry are a challenge not only to the operators but also the machines in particular. Heat, dust, vapours and dirt stress the facilities and often bring them to their limits. Among other things, a continuous lubrication of the facilities is crucial to prevent the resulting machine failures.

| Challenges | Solution |

|---|---|

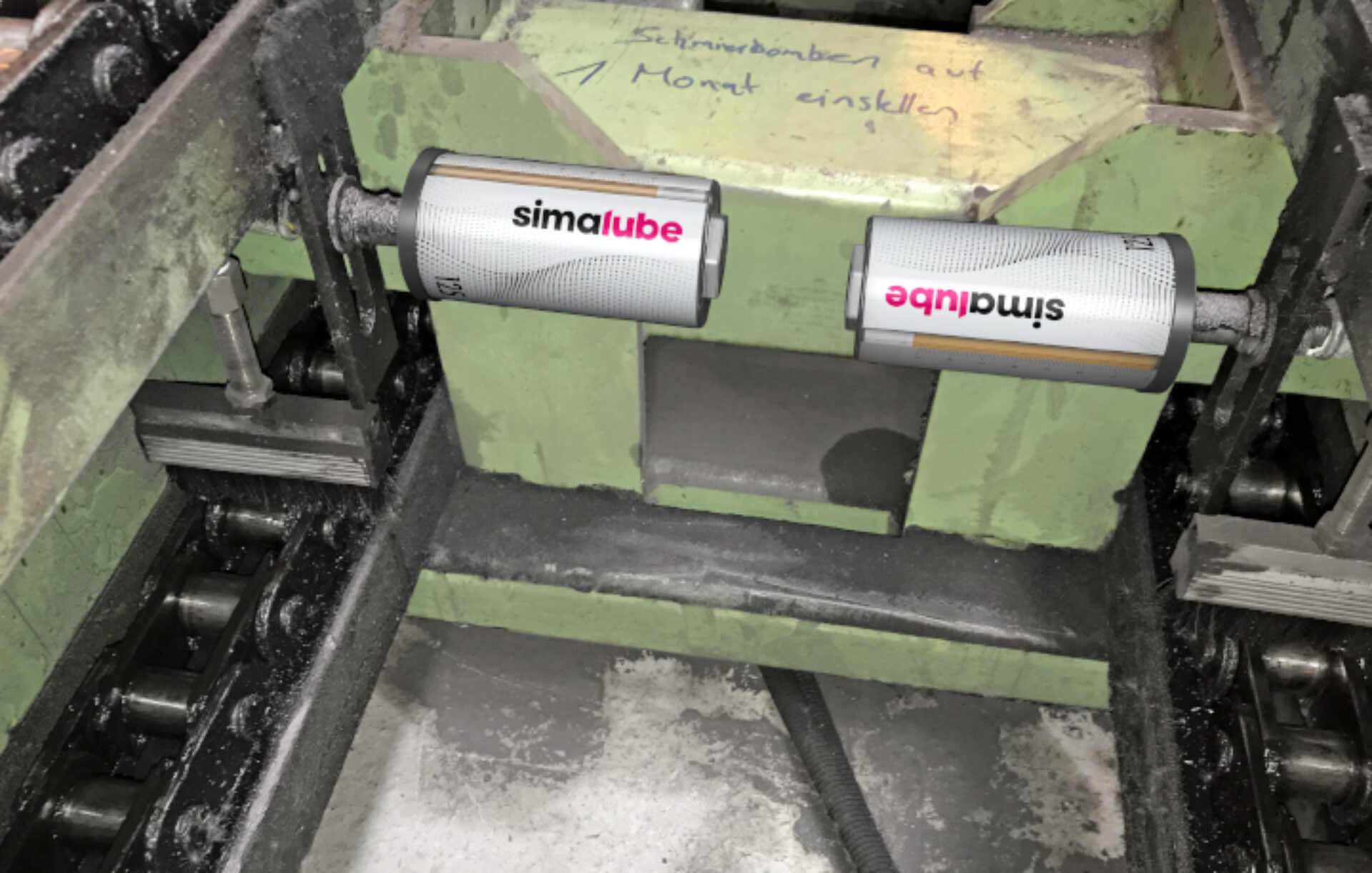

| Rough use | Simalube lubricators |

| Temperature fluctuations, risk of damage to the installations | Partial special accessories for tight spaces |

| High load on the systems | IMPULSE connect: Digital monitoring and configuration of the lubrication points via Bluetooth®. The lubrication points can be monitored from a distance of 20 m. The device can be used to increase the pressure up to 10 bar |

| High back pressure | Accessories and hose so that the dispensers can be mounted outside hazardous areas |

Areas of application and advantages

| Areas of application for Simalube in steel production processes | Plants/machines in steelworks | Simalube applications in steelworks |

|---|---|---|

| Coking facility | Conveyor systems | Bearings |

| Refining of pig iron | Fan units | Sliding rails |

| Sintering facility | Gearboxes/motors | Chains |

| Alloying of steel | Blower motors | Joints |

| Blast furnaces | Pumps | Toothed racks |

| Vacuum unit | Mixers | Arms and links |

| Desulphurization | Strainers | Pinions |

| Continuous casting facility | Motor bearings | Guide rollers |

| Removal of slag | Cranes | Gas valves |

| Ingot casting | Ovens | Couplings |

| Filling of the converter | Rollers | |

| Roll stands |

| Benefits from automatic lubrication | Advantages of simalube lubrication systems |

|---|---|

| Less downtime of the facilities | Reliability: Once installed, the lubrication points are reliably lubricated and never forgotten |

| Reduction of wear and longer service life of the components | The hermetically sealed system prevents contamination by dust and debris (IP68) |

| Increased operational safety since manual lubrication is not required | Reduction of service requirements and maintenance costs: Manual lubrication is no longer necessary meaning fewer disruptions and a huge saving of time |

| Long-term supply of lubrication points that are heard to reach | Longer service life of machines thanks to continuous and accurate lubrication |

| Less time required for maintenance | Flexibility: The running time is adjustable from 1–12 months |

| No need to shut down the machines during maintenance | |

| Installation is possible even in very narrow spaces |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.