Constant use of rail vehicles leads to increased wear of the flanges and rail flanks due to the friction between wheel and rails. Unwanted squeaking noises are a further unpleasant consequence especially in tight corners. In order to ensure trouble-free rail transport, the individual components in the three areas of depots, vehicles and infrastructure systems must always be optimally maintained - and this under the most varied weather conditions, continuous impact load and vibrations.

| Challenges | Solution |

|---|---|

| Outdoor applications with large temperature fluctuations | Simalube lubricators with protection against vibrations, often installed remotely |

| Vibrations on vehicles |

Areas of application and advantages

| Simalube application areas for railways, subways and trams | Simalube applications for railways, subways and trams |

|---|---|

| Adjustment of points | Bearings |

| Lifting equipment | Pinions |

| Locking of points | Gearwheels |

| Gearboxes and motors | Guides |

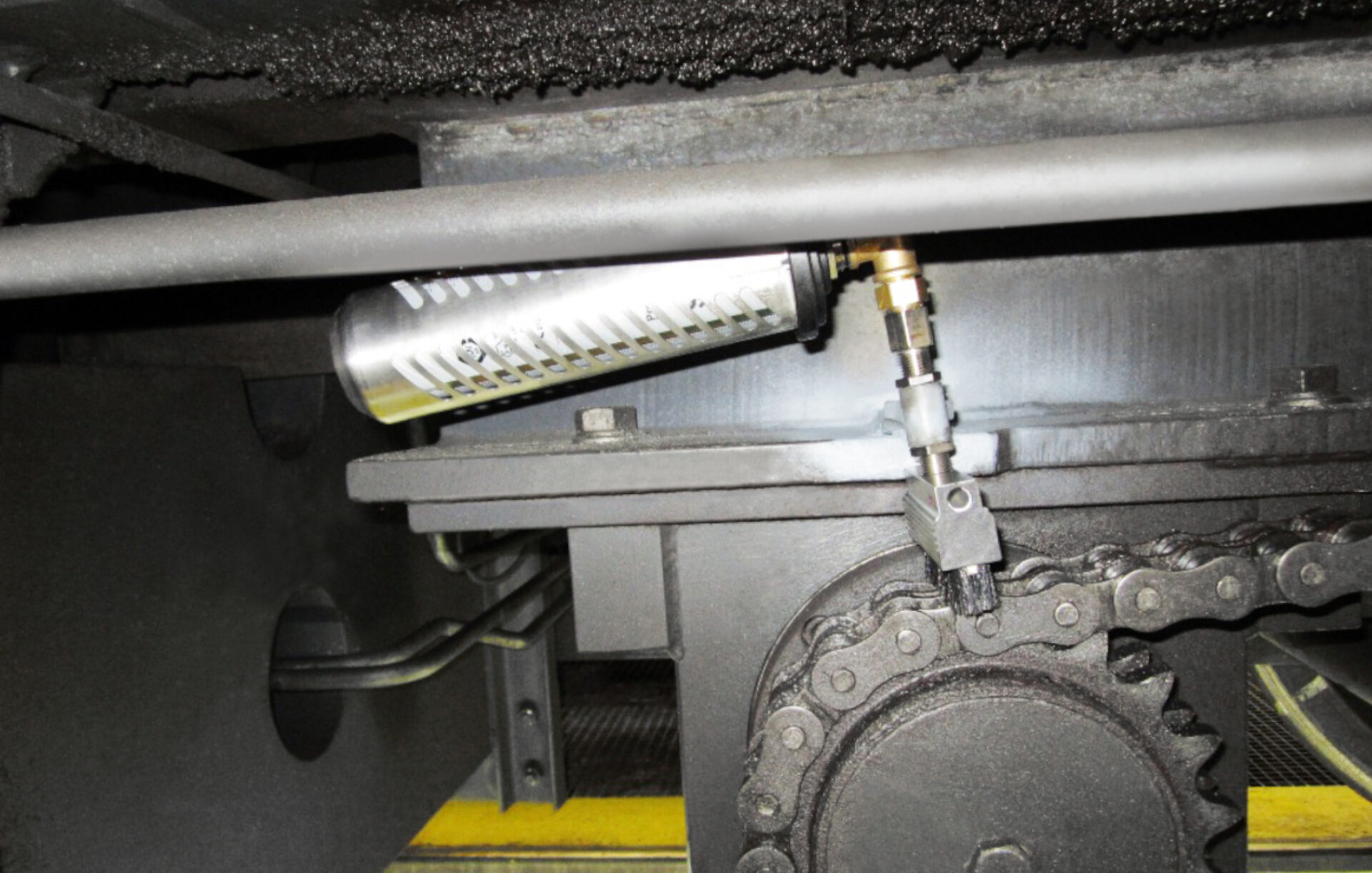

| Rails (curves) | Chains |

| Grinding equipment | Couplings |

| Signal adjustments | Spindles |

| Pantographs | |

| Buffers | |

| Chassis |

| Benefits from automatic lubrication | Advantages of simalube lubrication systems |

|---|---|

| Increased operational safety | Installation is possible in tight spaces |

| Reduced downtime | Reduction of service costs and maintenance costs: manual lubrication is eliminated, resulting in fewer operations and time saving |

| Optimization of system availability | Longer component life thanks to continuous and precise lubrication |

| Reduced noise level | The progress of the dispensing process can be monitored at any time thanks to the transparent housing (quantity control) |

| Constant supply of hard to reach lubrication points | Reliability: once installed, the lubrication points become reliably supplied with lubricant and will no longer be unattended |

| Flexibility: Running times are infinitely adjustable from 1-12 months |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.