Machines and systems in the paper industry have to function perfectly under extreme operating conditions. In material processing, high temperatures, impurities and increased humidity are often encountered, which cause problems for the machine components and significantly impair the service life of the bearings and chains. The machine parts are also exposed to high stresses in the refining and finishing process steps. In most cases, the equipment runs in continuous operation, so a failure can result in high production losses. To withstand these extreme operating conditions and avoid unplanned downtime, reliable lubrication is essential.

| Challenges | Solution |

|---|---|

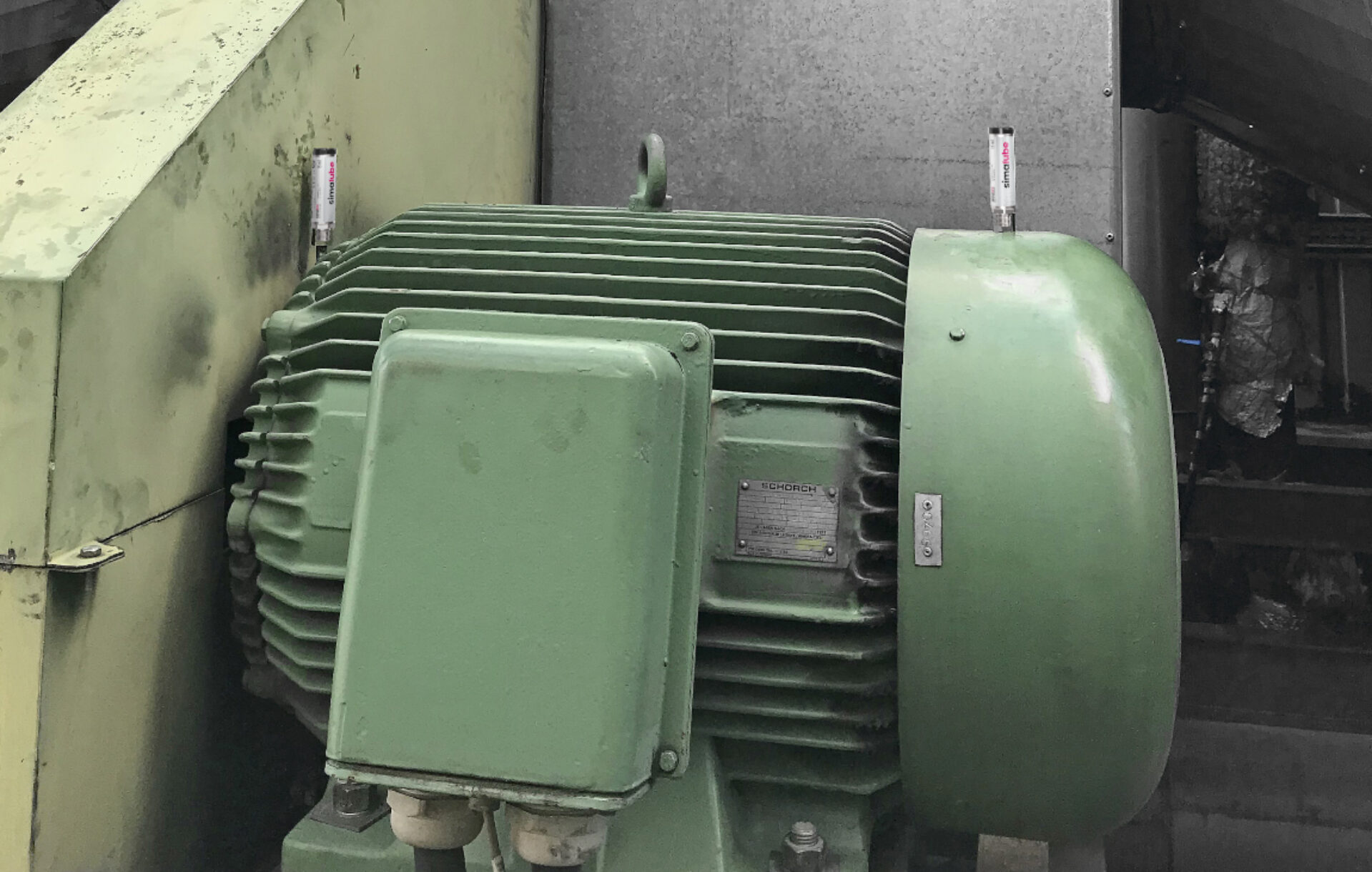

| No contamination of the manufactured products during production | Simalube mostly screwed in directly at the lubrication point. |

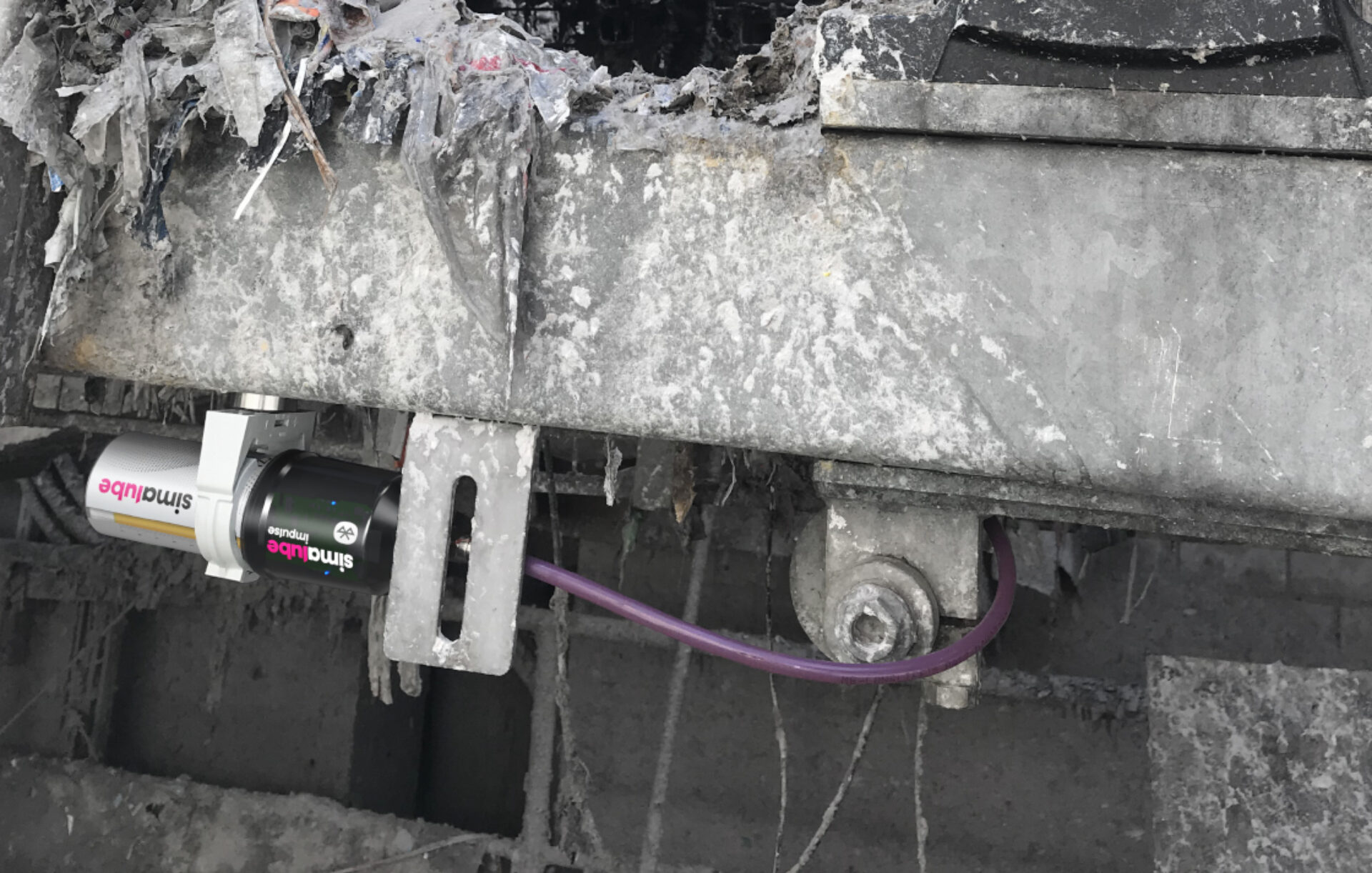

| High air humidity, sometimes high ambient temperatures | IMPULSE connect: Digital monitoring and configuration of the lubrication points via Bluetooth®. The lubrication points can be monitored from a distance of 20 m. The device can be used to increase the pressure up to 10 bar. |

Areas of application and advantages

| Areas of application for Simalube in the paper industry | Your benefits from automatic lubrication with Simalube | Advantages of the Simalube lubrication system |

|---|---|---|

| Vacuum units | Increased operational safety | Reduction in servicing and maintenance: no more lubrication by hand, this results in enormous savings of time costs |

| Lengthways-/cross-cutters | Less downtime | It is not necessary to switch the machines off while they are being serviced |

| Pulpers, dryers | Permanent supply of hard to reach lubrication points | A longer working life for the systems thanks to continuous and precise lubrication |

| Conveyor belt systems | Less time spent on maintenance | Flexibility: The runtimes can be set over a continuously variable range of 1-12 months |

| Chain conveyors | Reduction of wear and longer service life of the components | Only one type of lubricator is required per application. This makes it possible to reduce inventory costs |

| Drums | The hermetically sealed system prevents the penetration of dirt (IP68) | |

| Roller transport systems | ||

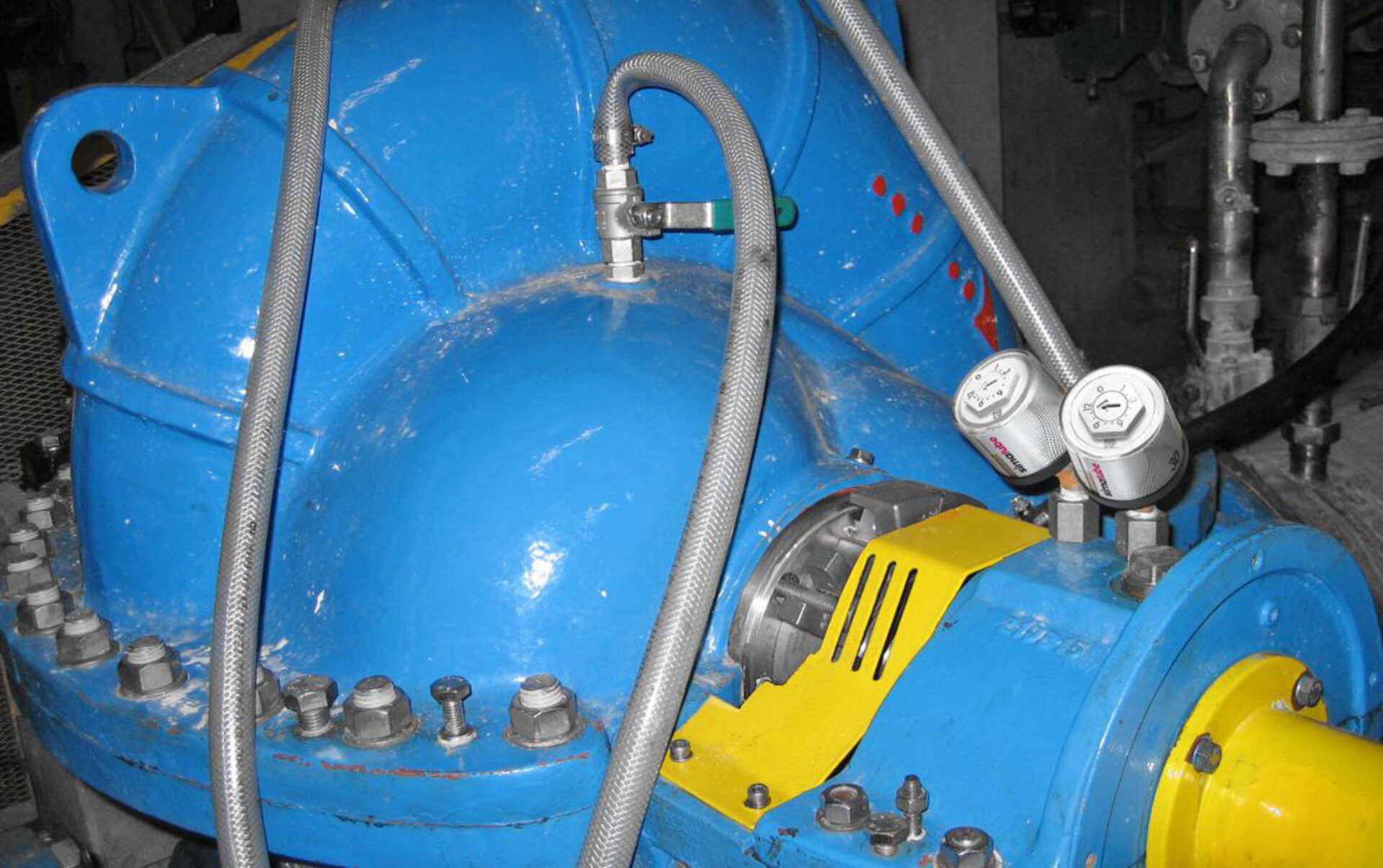

| Pumps |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.