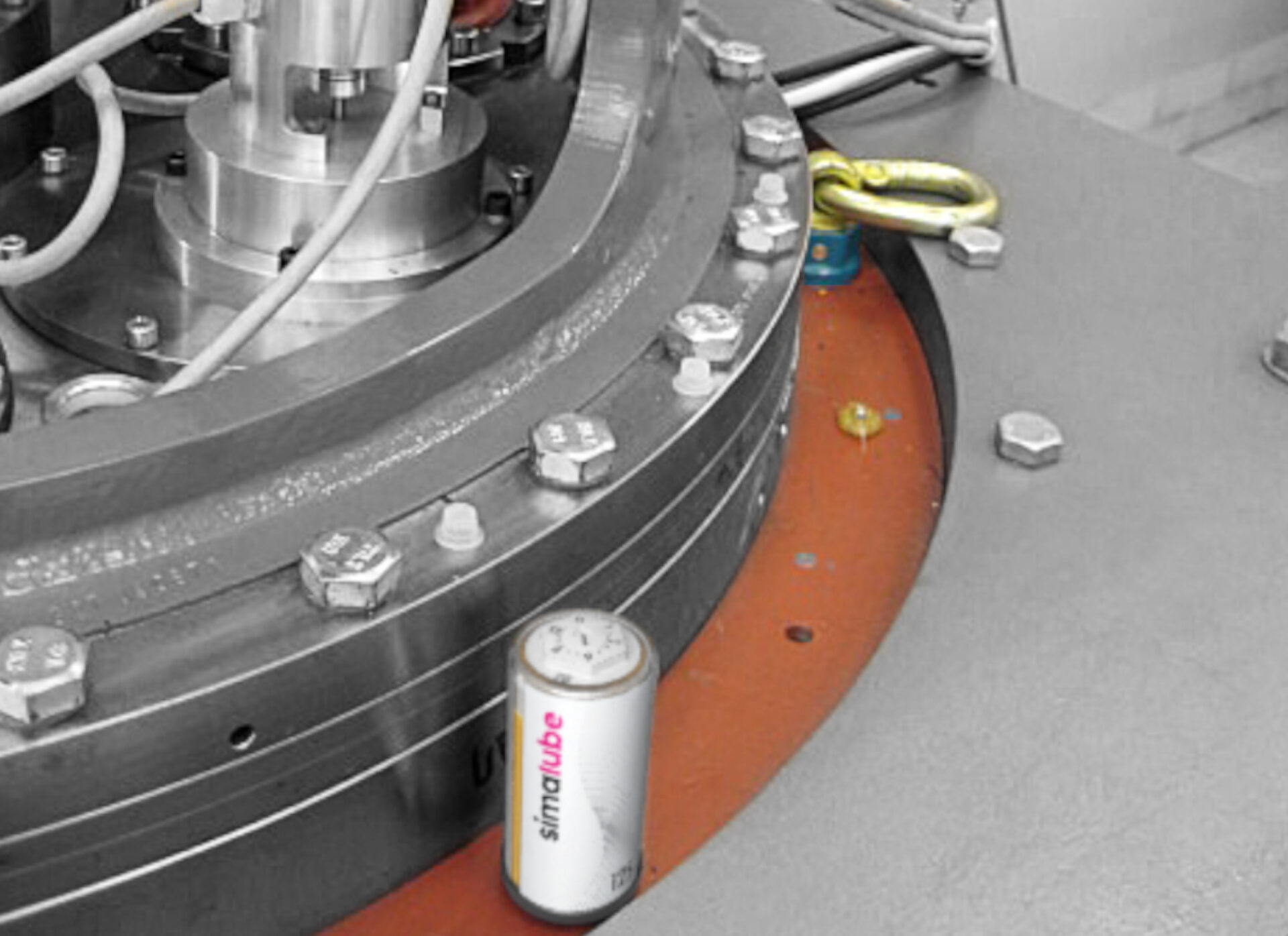

The demand for technical reliability is significantly higher on a ship than in a vehicle on land: lasting performance in a rough environment (high stress from vibration, high salt content in the air, etc.) and a long lifespan are essential. simalube lubricators help fulfill these exacting demands. They automatically and continuously lubricate not only ball bearings in motors and pumps, but also chains, wire cables, guides, toothed gears, swiveling mechanisms, and more. Through the reliable care of the mechanical components with lubricant, disruptions and breakdowns can be avoided. simalube greatly reduces maintenance efforts and costs.

| Challenges | Solution |

|---|---|

| Corrosion due to salty ambient air | Simalube lubricant dispenser, approved in all ATEX areas |

| Large temperature fluctuations | IMPULSE connect: Digital monitoring and configuration of the lubrication points via Bluetooth®. The lubrication points can be monitored from a distance of 20 m. The device can be used to increase the pressure up to 10 bar. Special accessories (rope lubrication, elevator lubrication). |

| Lubrication points in hazardous areas |

Areas of application and advantages

| Simalube applications on ships | Advantages of the simalube lubrication system |

|---|---|

| Ventilator drives and bearings | Reduction of service requirements and maintenance costs: because manual lubrication is no longer necessary, less labour is required and time savings are great |

| Waste water systems | Shutting down the machines for maintenance is no longer necessary |

| Pump motors and seals | Longer service life of machines thanks to continuous and precise lubrication |

| Laundry and purification systems | Flexibility: The running time is adjustable from 1–12 months |

| Compressors | Only one type of lubricator is needed per application. This reduces storage costs |

| Distillation systems | The hermetically sealed system prevents contamination by dust and debris (IP68) |

| Waste incineration systems | Decrease in corrosion-related failures |

| Fire protection systems | |

| Elevators/escalators | |

| Chains and steel cables | |

| Cranes/swivel mechanisms |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.

Discover our fully automatic lubrication solutions at Pomac Lub-Services or browse the ILC range