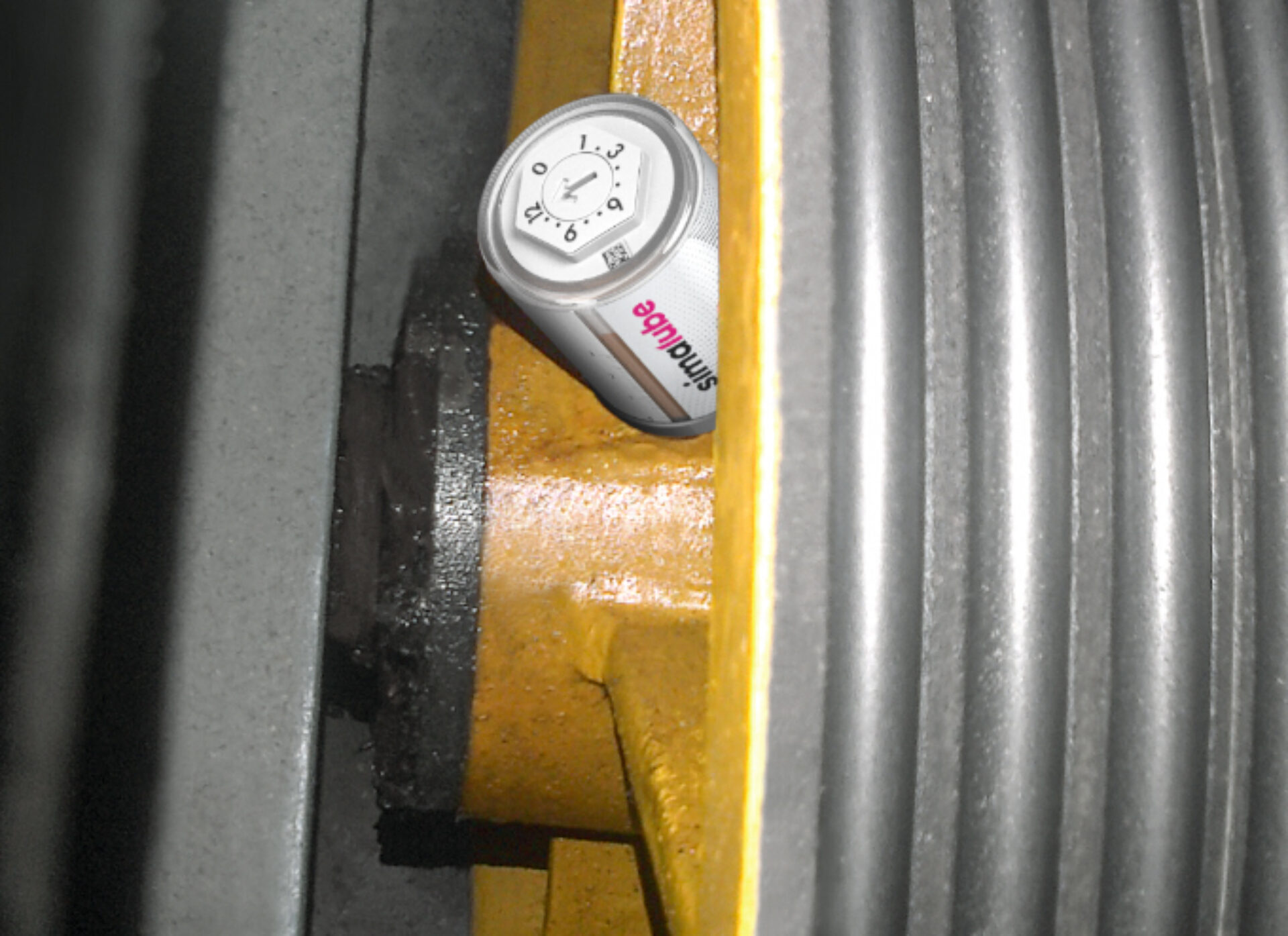

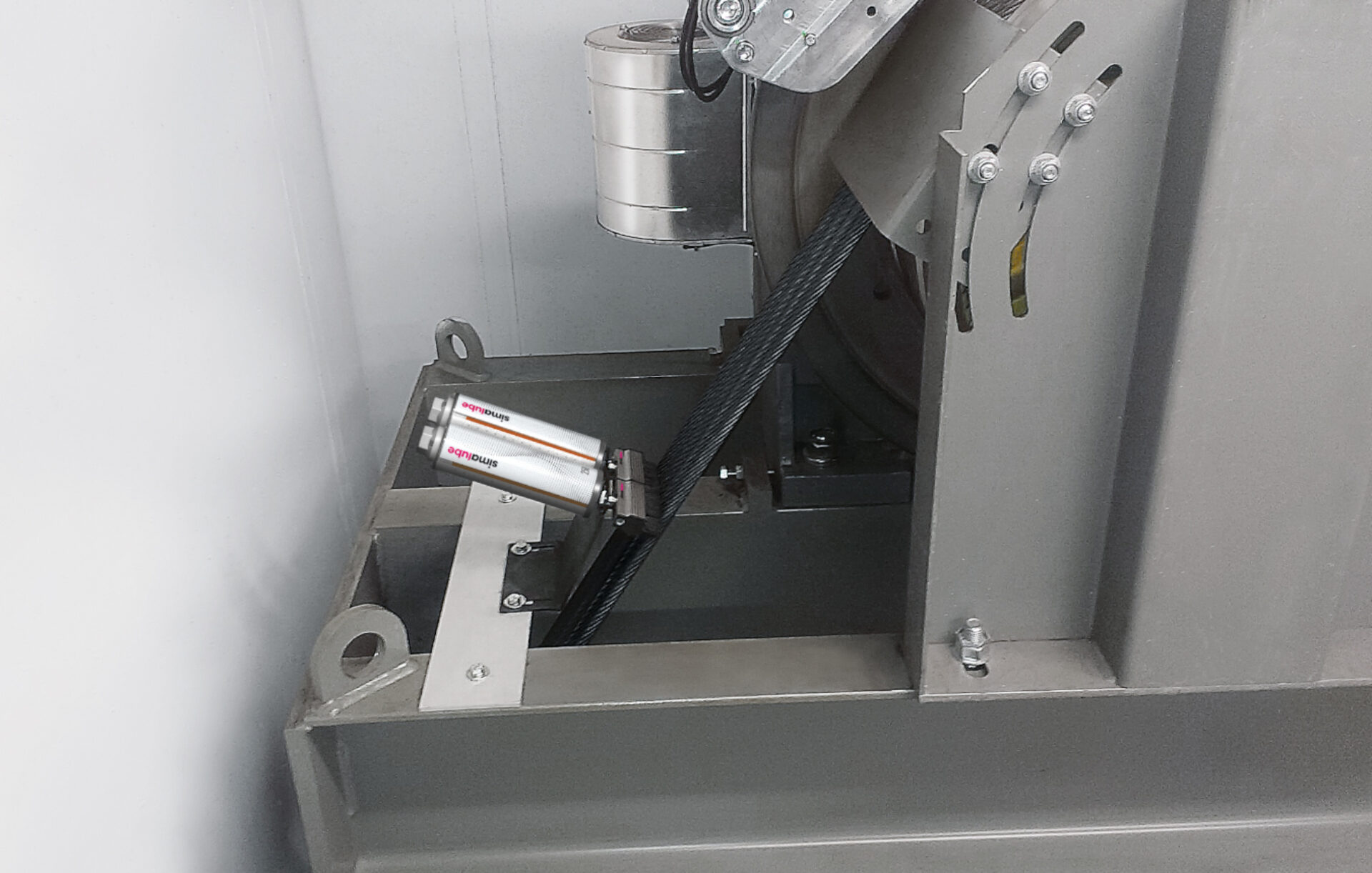

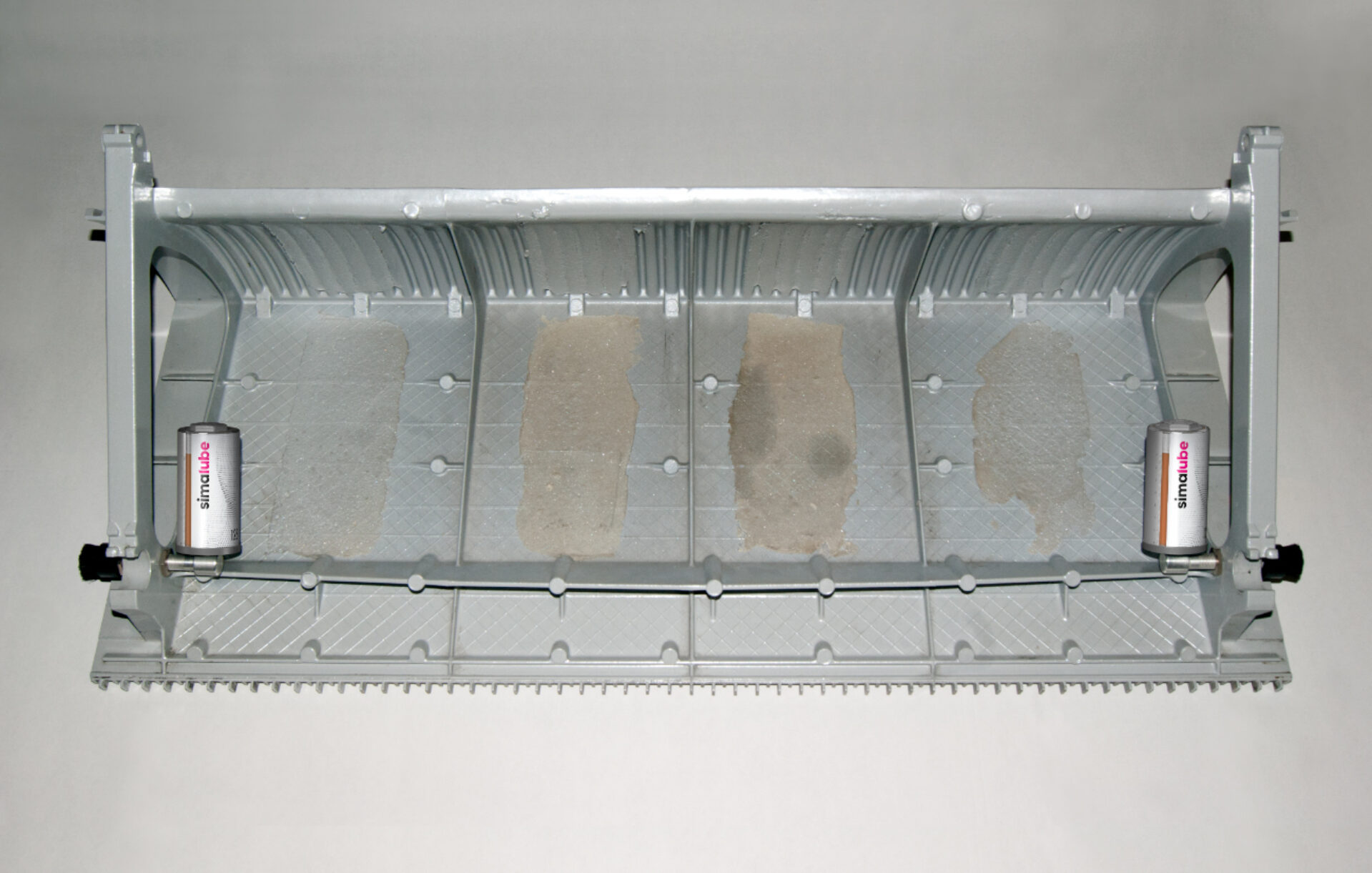

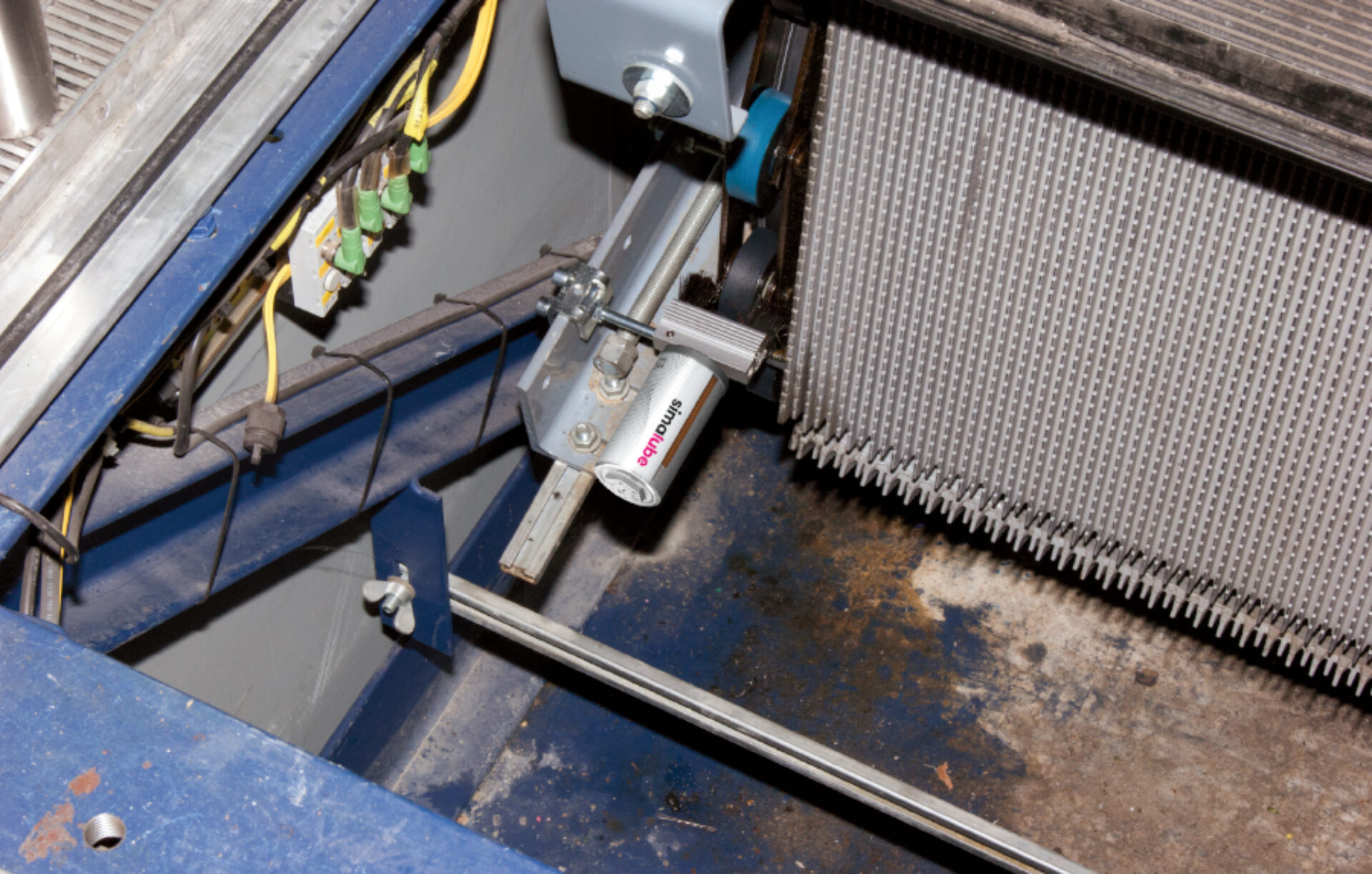

Guide rails and pulleys of elevators must be constantly lubricated to avoid dry friction. Another application is the maintenance of elevator ropes with rope care products. Due to the exact dosage of the lubricant or rope care product, the simalube lubrication system reduces maintenance and cleaning work. It is therefore particularly suitable for high-maintenance elevators in outdoor areas and panoramic elevators.

| Challenges | Solution |

|---|---|

| No pollution of the shaft walls for lifts | Simalube and special brushes for lubricating guides and ropes |

| Longest possible maintenance intervals | |

| Minimization of wear |

Areas of application and advantages

The easy-to-use Simalube lubrication systems guarantee optimal care of elevators and escalators. These special lubrication systems are exceptionally reliable and efficient. Assembly sets are available for retrofitting elevators and escalators made by the best-known manufacturers.

| Simalube area of application for elevators | Specific benefits for elevators | Benefits of the simalube lubrication system |

|---|---|---|

| Guide rails | Reliable lubrication of guide rails and traction cables | Reduction of service requirements and maintenance costs |

| Diverter pulley | Elevator runs quietly | No more oil spillage or splashes |

| Elevator ropes | Containers to catch excess oil no longer required | Simple to retrofit existing installations |

| Improved occupational safety (no risk of slipping on excess oil) | ||

| Constant application of lubricant | ||

| Stepless setting of lubricant dispensing time from one month to one year | ||

| Refillable oil lubricator |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.