| Challenges | Solution |

|---|---|

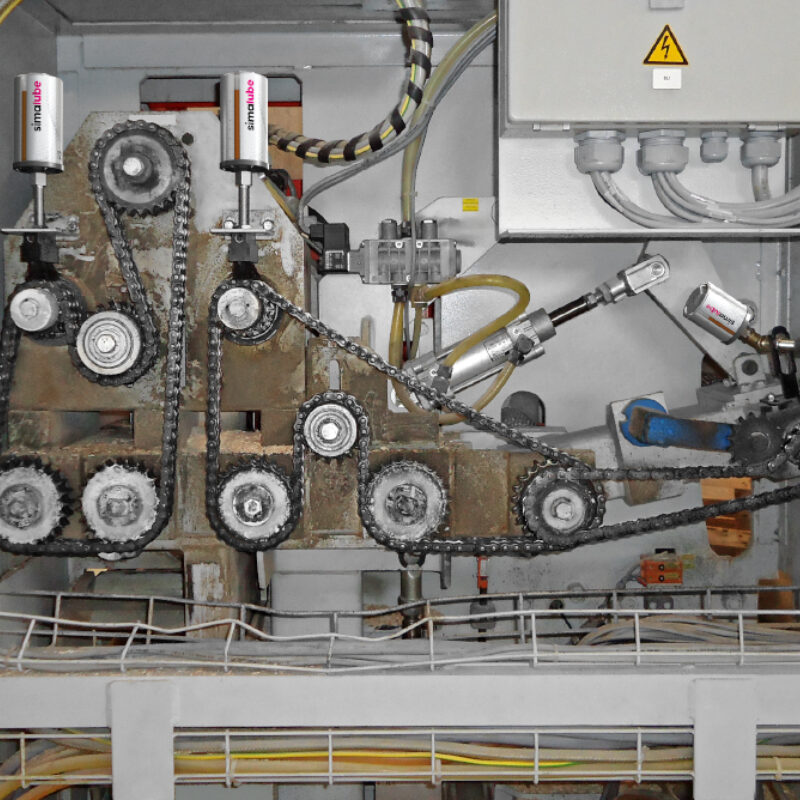

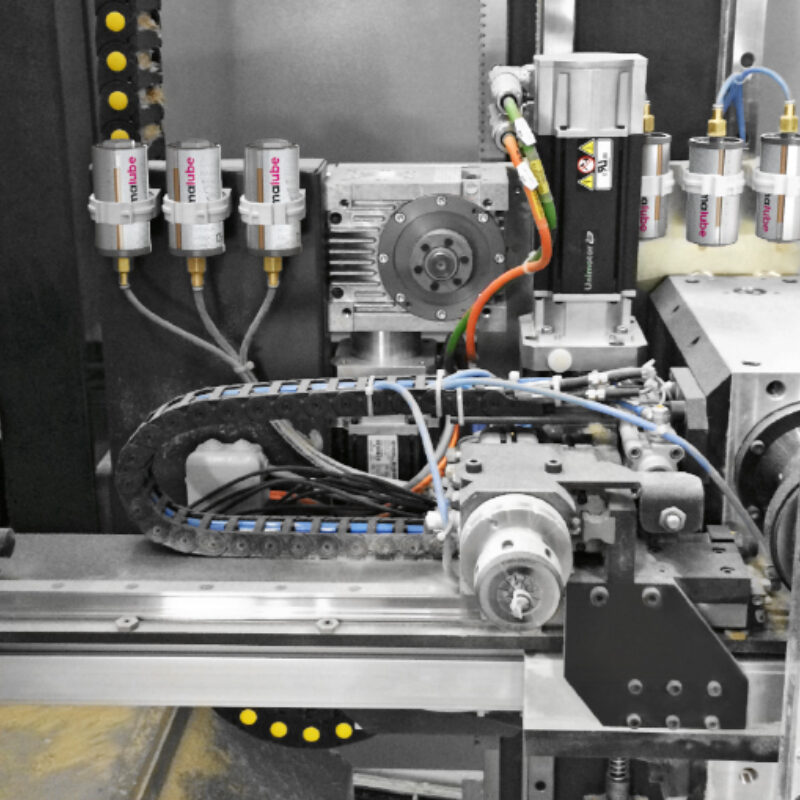

| Heavy contamination due to dust and sawdust | Simalube grease and oil dispenser |

| Lubricators must be attached to rotating machine parts | IMPULSE connect: Digital monitoring and configuration of lubrication points via Bluetooth®. The device can be used to increase the pressure up to 10 bar. |

Areas of application and advantages

| Simalube applications in the wood processing industry | Further benefits |

|---|---|

| Conveyor systems/chains | Reliability: Once installed, the lubrication points are reliably lubricated and never forgotten |

| Vibration channels | The hermetically sealed system prevents contamination by dust and debris (IP68) |

| Track rollers | Reduction of service requirements and maintenance costs: Manual lubrication is no longer necessary meaning fewer disruptions and a huge saving of time |

| Trimming systems/chipping systems | Longer service life of machines thanks to continuous and accurate lubrication |

| Loading cranes | Flexibility: The running time is adjustable from 1–12 months |

| Drives/motors | No need to shut down the machines during maintenance |

| Saws of all types Spindles/ducts | |

| Debarking systems | |

| Transportation systems |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.