Construction machinery and its components must be operational at all times and in all weather conditions under extreme working loads. High functionality and productivity of the machines must be guaranteed at all times - without downtimes. This is ensured, among other things, by the automatic simalube lubricator, which continuously supplies the construction machines with sufficient lubricant over 1-12 months.

| Challenges | Solution |

|---|---|

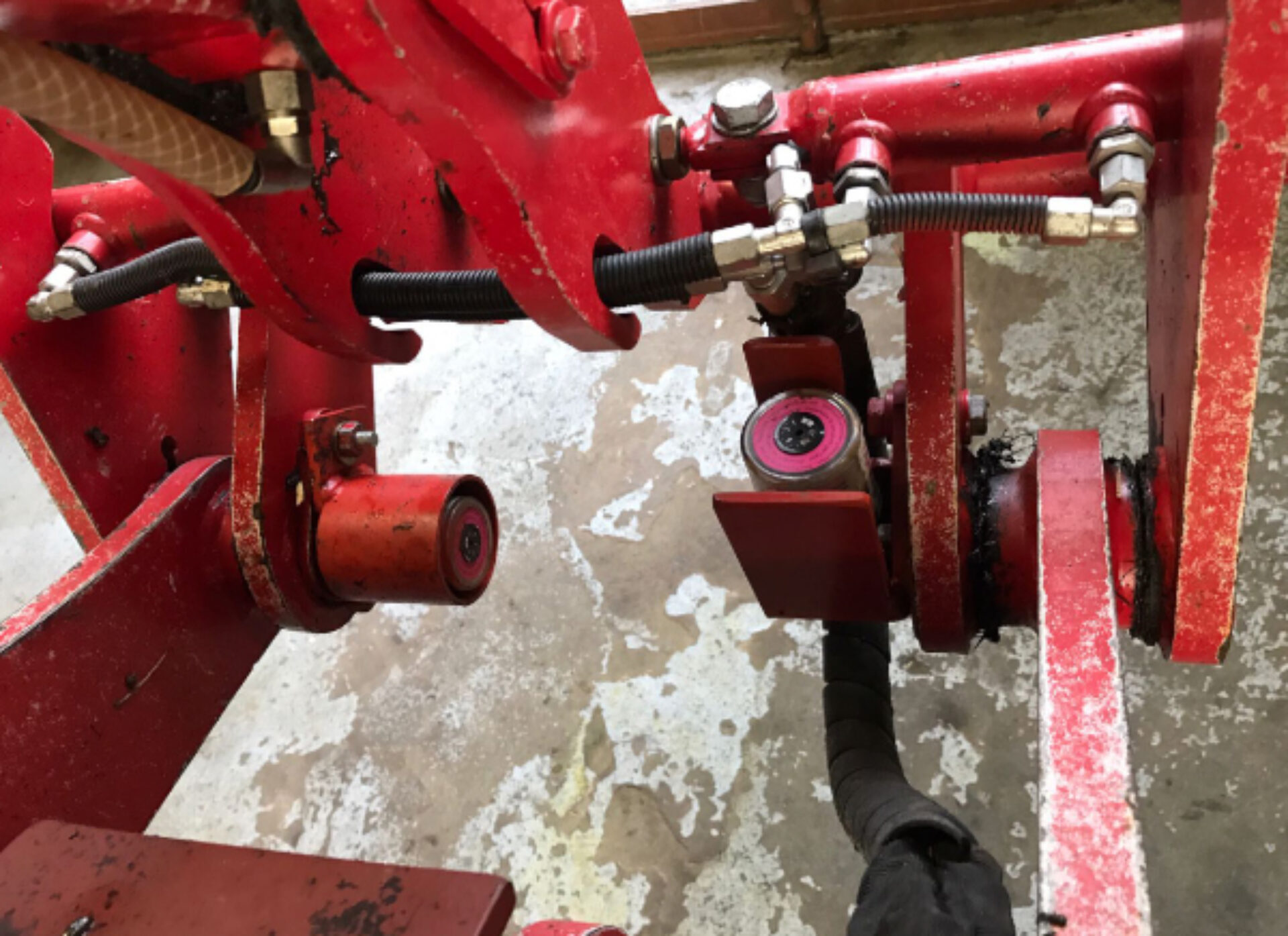

| Rough use often outdoors in adverse weather conditions | Due to the large lubrication quantities, mostly Simalube 125 ml and 250 ml are used |

| High stress due to vibrations and impacts | Accessories for mounting and protecting the lubricant dispensers |

| Simalube IMPULSE connect: Digital monitoring and configuration of the lubrication points via Bluetooth®. The device can be used to increase the pressure up to 10 bar |

Areas of application and advantages

| Benefits of the simalube lubrication system | Typical installations | Typical applications |

|---|---|---|

| Reliable, autonomous lubrication with low maintenance requirements | Conveyor belts | Bearings |

| Long maintenance intervals | Cranes | Chains |

| Equipment is lubricated for longer periods of time and does not have to go to the shop for maintenance work and maintenance staff has to visit construction sites less often | Excavators | Guides |

| Dump trucks | Gears | |

| Vibrating plates | Ropes | |

| Mixers | Cable drums | |

| Crushers | Joints | |

| Compressors | Winches | |

| Concrete mixers | ||

| Rollers |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.