The chemical industry is a highly industrialized branch of industry. With the help of a continuous supply of lubricants from simalube, machine downtimes can be prevented or shortened. This results in efficient and profitable production.

| Challenges | Solution |

|---|---|

| High demands on the resistance of the products | Simalube lubricators are in many cases filled with lubricants specially suited for the chemical industry. |

| The use of approved special lubricants require a product that can be used flexibly | |

| Use of the products in potentially explosive atmospheres, ATEX. |

Areas of application and advantages

| Benefits of the Simalube lubrication system | Typical installations | Typical applications |

|---|---|---|

| Reliable, autonomous lubrication with low maintenance requirements | Conveyor belts | Bearings |

| Long maintenance intervals | Cranes | Chains |

| Equipment is lubricated for longer periods of time and does not have to go to the shop for maintenance work and maintenance staff has to visit construction sites less often | Excavators | Guides |

| Dump trucks | Gears | |

| Vibrating plates | Ropes | |

| Mixers | Cable drums | |

| Crushers | Joints | |

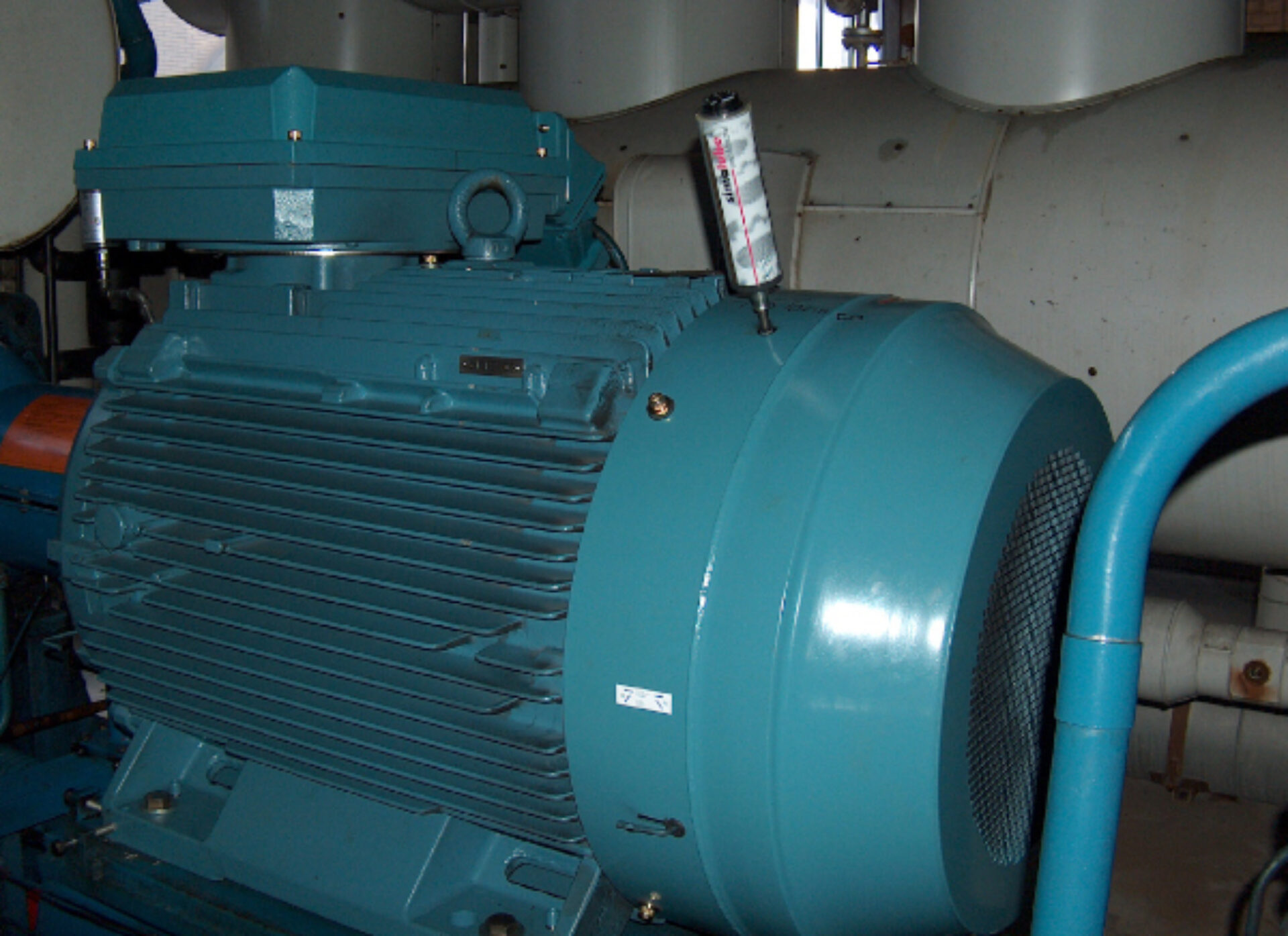

| Compressors | Winches | |

| Concrete mixers | ||

| Rollers |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

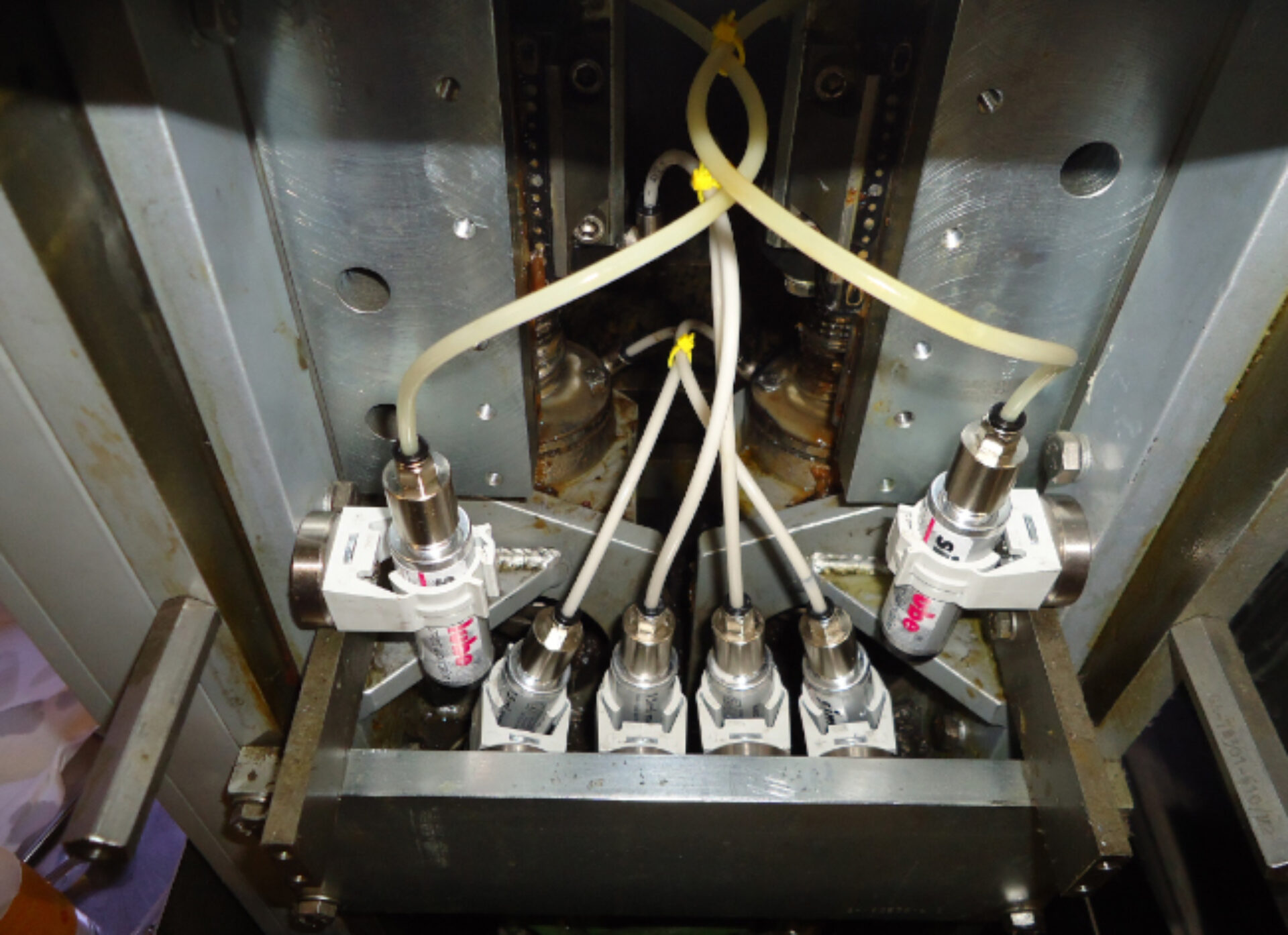

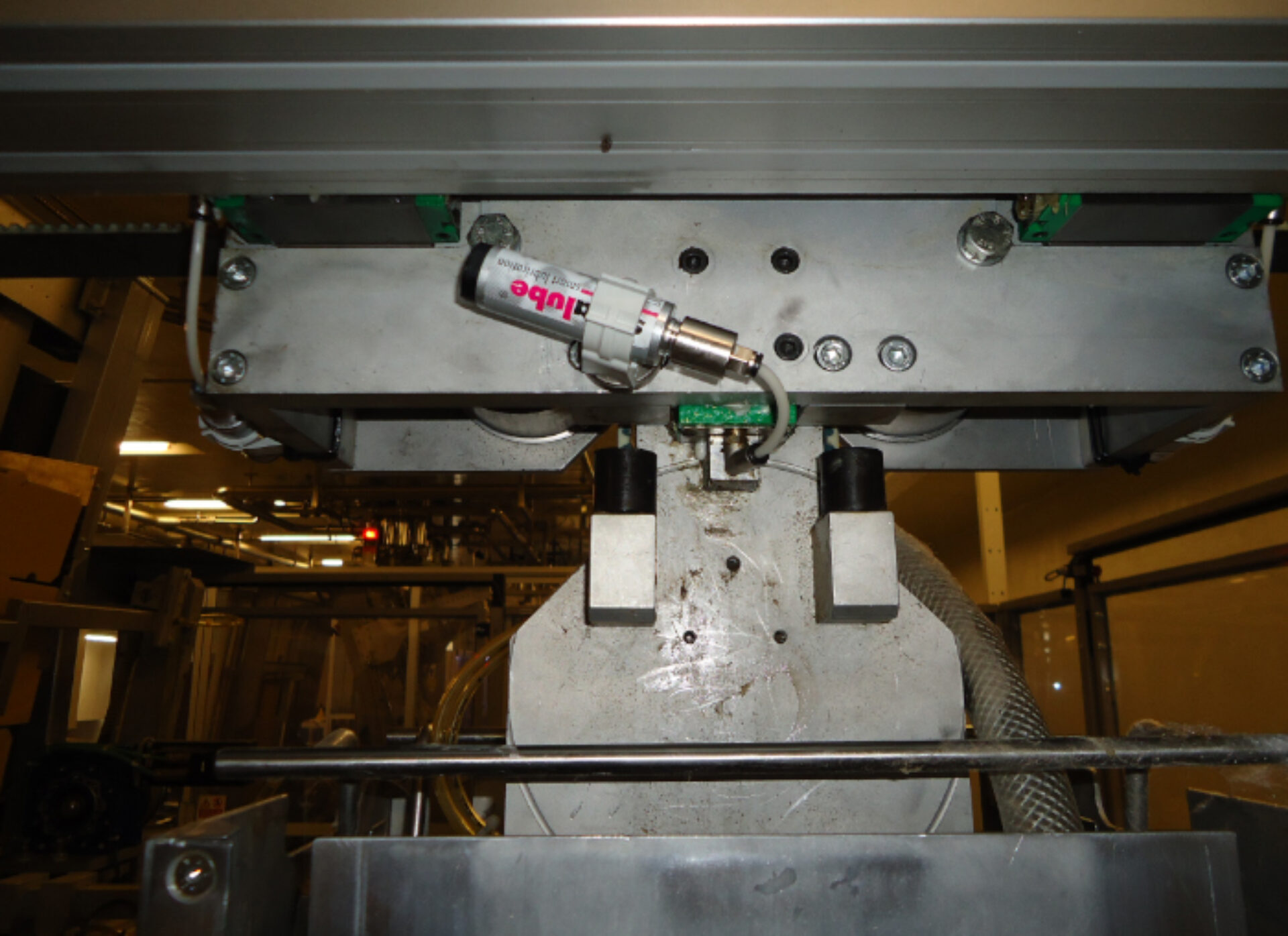

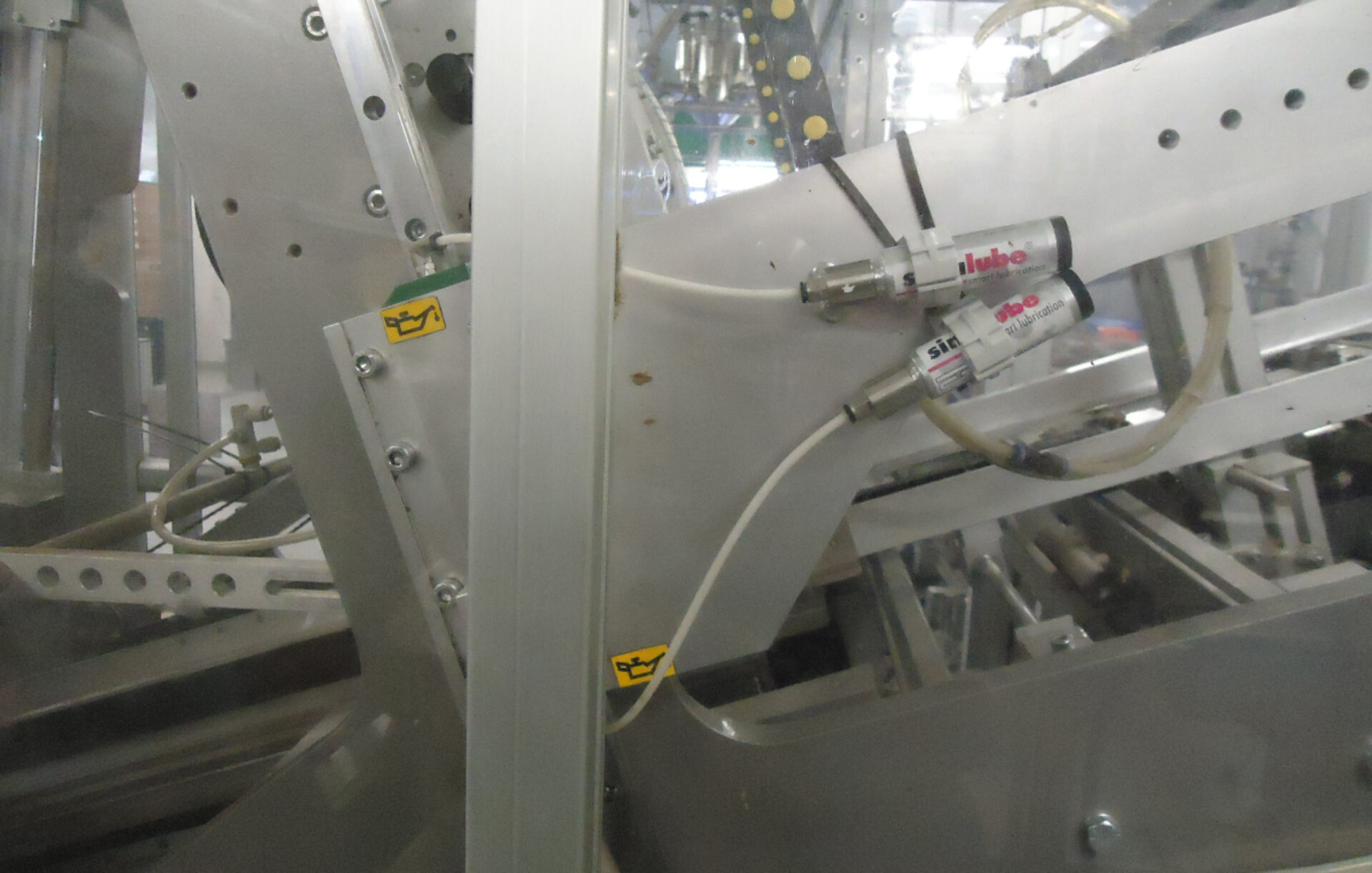

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.